PVC leather and PU leather are collectively called artificial leather. PVC and PU are both polyvinyl chloride. PU feels soft and PVC feels hard.

The processes of both are relatively complex. During the manufacturing process of PVC leather, plastic particles must be hot-melted and stirred into a paste, and then evenly coated on the T/C knitted fabric base according to the specified thickness. The base is then put into a foaming furnace for foaming, so that it has a softness that can adapt to the production of various products and different requirements. It is surface treated at the same time as it comes out of the oven; the manufacturing process of PU leather is more complicated than PVC leather. , since the PU base fabric is a canvas PU material with good tensile strength, in addition to being coated on the base fabric, the base fabric can also be included in the middle so that the existence of the base fabric cannot be seen from the outside.

What are the advantages of the two? PVC leather is mostly used in linings or non-weight-bearing parts, and can also be used to make children’s shoes; PU leather can be used in footwear fabrics or weight-bearing parts. PVC coating is generally also used for bag making. If the two are burned with fire, the taste of PU will be much lighter than that of PVC.

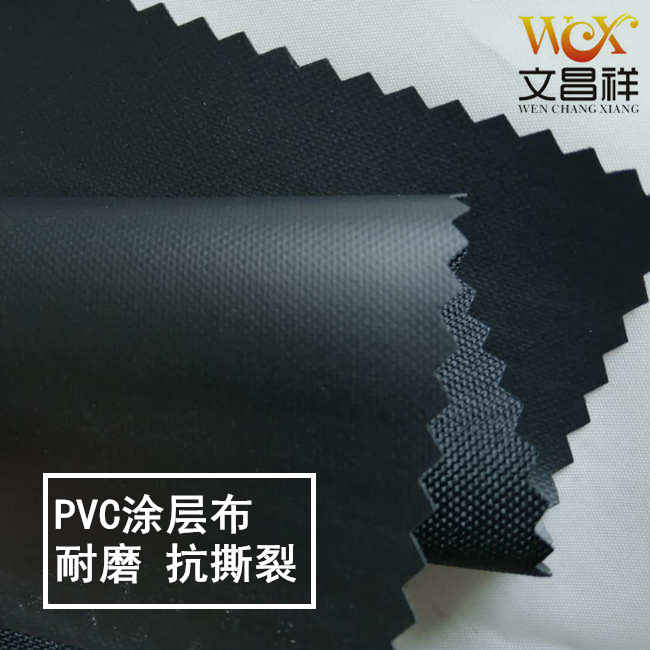

PVC coated Oxford cloth is now widely used in tents, car awnings, train covers, ship covers, open-air cargo yard covers, railway and road transportation, warehousing, coal mines, industrial and agricultural fields, etc.

Textile’s main products are Oxford cloth series: waterproof Oxford cloth, flame-retardant Oxford cloth, coated Oxford cloth, fluorescent Oxford cloth, etc. If you are interested in or have questions about the products of Suzhou Textile Co., Ltd., please contact the online customer service on the web page, or leave a message for dedicated service. Meet all your needs.

</p