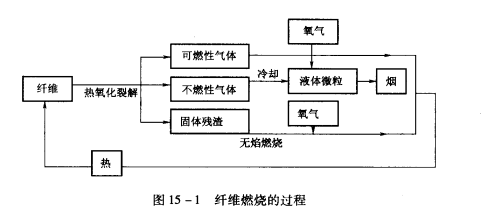

Flame retardancy refers to reducing the flammability of materials in flames and slowing down the spread of flames. When the flame is removed, it can quickly self-extinguish and no longer stain. 1. Combustion process and conditions The combustion process of fiber, that is, from ignition to final combustion product, requires a series of complex physical and chemical changes. These changes have no obvious stages and can usually be divided into: (1) Textile materials Thermal cracking produces flammable gases, non-flammable gases and carbonized residues. (2) Flammable pyrolysis, when the temperature reaches the ignition point or encounters other fire sources, it ignites and releases heat, light and smoke. (3) The heat released causes the fiber to continue to crack and burn, causing the flame to spread. The fiber burning process is shown in Figure 15-1.

It can be seen from Figure 15-1 that the conditions necessary for the combustion of fiber polymers are: (1) Thermal cracking of polymers produces flammable gases. (2) Oxygen or oxidants exist. (3) There is a heat source. In this way, the three elements of combustibles, heat and oxygen constitute the combustion cycle. In addition to the gas-phase flaming combustion of the above-mentioned flammable gases and oxygen, there is also the solid-phase flameless combustion of the carbonized residue formed during cracking and oxygen. Flameless combustion requires much higher temperatures than flaming combustion, but this flame retardant can also burn the material, sometimes causing a sudden burst of flame to become a flaming combustion.

AAA anti-UV fabric net FSGRETEGSDFW

Combustion Processes and Conditions Composite Fabric Information

Flame retardancy refers to reducing the flammability of materials in flames and slowing down the spread of flames. When the flame is removed, it can quickly self-extinguish and no longer stain. 1. Combustion pr…

This article is from the Internet, does not represent Composite Fabric,bonded Fabric,Lamination Fabric position, reproduced please specify the source.https://www.yjtextile.com/archives/37516