The lint produced by the cotton gin or the lint cleaned by the lint cleaning machine is usually sent to the baler for packaging through the lint collecting device. The function of the cotton collection device is to use the rotating cotton collection net to separate the lint from the air flow, so that the loose cotton fibers gather on the surface of the cotton collection net and are pressed into cotton sheets, and then sent to the baler for packaging. Some small impurities and some short fluff enter the dust cage air duct through the cotton collection mesh with the airflow, and finally enter the dust removal facility.

Cotton collection methods include single machine collection and joint collection. When collecting cotton in a single machine, the lint needs to be transported to the baler using a conveyor belt (curtain) or manually, resulting in low production efficiency and poor working conditions. Joint cotton collection realizes continuous production, improves production efficiency, saves labor, and improves the production environment and working conditions, so it has been widely used.

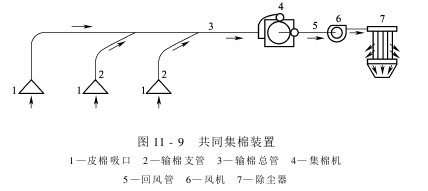

The common lint collecting device mainly uses airflow to collect the lint produced by multiple gins and sends it to the main lint collecting box. It is also a relatively typical suction type pneumatic conveying device. It mainly consists of lint suction nozzles, cotton transport branch pipes, It consists of cotton main pipe, cotton collecting machine, return air duct, fan, dust collector and other components, as shown in Figure 11-9.

The cotton fibers brushed off by the sawtooth gin machine through the brush or air nozzle enter the lint triangular suction port with the air flow, and reach the cotton collector through the cotton transport branch pipe and the cotton transport main pipe. After passing through the cotton collector, the lint directly enters the baler and is packaged.

The size of the lint suction port depends on the size of the lint outlet of the gin or lint cleaning machine. Lint suction nozzles come in two shapes, one is a triangular box shape, and the other is a flat air duct shape. The former is usually used in a common cotton collecting device where the lint is rolled out of the sawtooth gin and collected directly. The suction nozzle of the triangular box is connected to the main cotton transport pipe through the cotton transport branch pipe. The latter is used in a common cotton collection device that collects lint after it has been cleaned by a lint cleaning machine. The flat air duct suction nozzle is directly connected to the cotton main pipe, also known as the suction pipe connection. Any cross-sectional area of the triangular box nozzle from the rectangular suction port to the circular cross-section outlet is equal, and the shrinkage angle of the designed triangular box is best controlled within 60°, so as to avoid the airflow from generating eddy currents in the suction nozzle, reducing The friction and collision between the fiber and the pipe wall reduces the exhaust resistance.

The diameter of the cotton branch pipe is usually 400~420mm. The intersection angle between the cotton transport branch pipe and the main pipe should be less than 30°. The diameter of the cotton main pipe should be increased according to the increase in the number of access branch pipes. When determining the diameter of the return duct, the air leakage rate of the cotton collector must be taken into consideration. The wind speed in the return air duct should be controlled at about 10m/s.

Cotton collecting fans usually use 4-72 series medium pressure fans. The total pressure of the fan is greatly affected by the type of dust collector. The air volume of the fan is determined based on the total exhaust air volume of cotton brushing, and factors such as air leakage of the cotton collecting machine are also taken into consideration.

The form of dust removal used in the cotton return air depends on the mesh size of the dust cage of the cotton collection machine. When the dust cage net is above 80 mesh, the effective fiber loss in the cotton collection return air is very small. If the dust concentration in the return air reaches the national emission standard, it can be directly discharged into the atmosphere without dust removal and purification.

However, when the mesh size of the dust cage net is small, the effective fibers are lost in the return air from the cotton collection. It is best to use two-stage dust removal to recover the effective fibers and make the dust-laden air concentration meet the national emission standards.

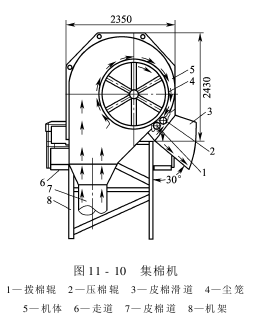

The cotton collector is a very important piece of equipment in the common cotton collection device. Its function is to separate the cotton fibers sent from the cotton collection pipe from the air flow, and remove some small impurities in the lint; it can also collect scattered cotton fibers in The surface of the dust cage is preliminarily compressed to form a uniform density of cotton batting to facilitate packaging.

The cotton collector is mainly composed of a dust cage, a cotton pressing roller, a cotton picking roller, a cotton inlet, an air outlet and a cover, as shown in Figure 11-10.

1. Dust cage

The dust cage is the main working part of the cotton collecting machine. It consists of a skeleton of flanges, flat steel and steel wires, and is wrapped with a certain number of stainless steel mesh or iron wire braided mesh, or it can also be a steel plate punched mesh. Usually 8 to 12 mesh wire mesh is used, and 80 mesh stainless steel mesh is also used. If it is a steel plate punched mesh, the aperture is 3mm.

There are two types of transmission methods for dust cages: roller type and central shaft type. The supporting wheel type is supported by four grooved supporting wheels at the bottom of the dust cage and is driven by friction with the dust cage flange. The central rotating shaft type rotates the central axis of the dust cage to make the dust cage run. Therefore, the dust cage of the former can be made into a vent type, while the dust cage of the latter can be made into a fully enclosed type. The fully enclosed dust cage has a larger ventilation area and cotton receiving area than the gallbladder type dust cage, but the sealing requirements are higher.

The diameter of the dust cage determines the processing capacity of the cotton collector. The processing volume mentioned here includes two meanings, namely lint processing volume and processing air volume. Generally, the diameter of the air duct type dust cage is larger, ranging from 1500 to 2000mm depending on the lint processing volume. The diameter of the fully enclosed dust cage is smaller, ranging from 1300 to 1600mm.

The width of the dust cage depends on the width of stainless steel, iron wire woven mesh or steel plate punched mesh. Generally, the width of stainless steel or iron wire woven mesh is 1000mm, the width of steel plate punched mesh is 1000~1300mm, and the width of stainless steel or iron wire woven mesh is 1000~1300mm. The effective width of the dust cage is 900~950mm.

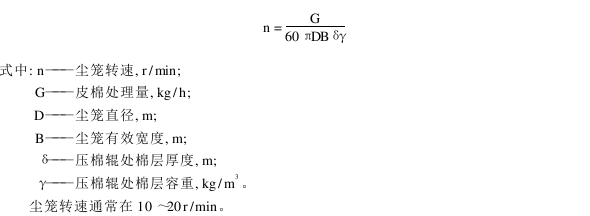

The speed of the dust cage rotation speed directly affects the thickness of the cotton layer on the surface of the dust cage. The thickness of the cotton layer is preferably 200~250g/m2. If the dust cage rotates too fast, the cotton layer will be too thin, resulting in increased loss of effective fibers; if the dust cage rotates too slowly, the cotton layer will be too thick, which will increase the exhaust resistance and even cause the sawtooth gin machine’s impurity discharge adjustment plate to fall. Cotton increased. The speed of the dust cage can be determined by the following formula.

2. Cotton pressing roller and cotton picking roller

Some cotton pressing rollers are on the surface of wooden rollers A smooth roller covered with tin sheets, sometimes made into a roller roller, which mainly plays the role of compacting the cotton on the surface of the dust cage. The surface linear speed of the cotton pressing roller is equal to the surface linear speed of the dust cage, but the rotation direction is opposite. There are many forms of cotton-picking rollers, some are pimp rollers, some are brush rollers, and there are roller rollers. Their function is to remove the cotton on the surface of the dust cage. The surface linear speed of the cotton-picking roller should be greater than or equal to the surface linear speed of the dust cage. And the rotation directions of the two are the same. The rubber plate should be used to seal the lint pressing roller and the lint picking roller and the machine casing.

3. Working process

Lint is transported into the lint collector by pneumatic transportation and attached to the dust cage The surface of the net. At the lint pressing roller, the loose lint is rolled into a batt, and then dropped from the surface of the dust cage by the lint roller. The lint is driven out of the machine by the opposite rotation of the pressing and lint rollers. And it slides down to the lint slide under the action of gravity, and then enters the baler. During the lint collection process, some dust enters the inside of the dust cage with the air, and enters the air pipe from the air outlet.

AAADF3RSEGDTHIU