1. Raw material selection

The scope of use of denim fabric raw materials is becoming increasingly broad. The selection of raw materials has broken through the pattern of mainly cotton, and a variety of raw material series have appeared, such as linen cotton, ramie, spun silk, polyester, spandex, differentiated fibers, wild fibers, etc., among which there are blends or interweaving.

For example, the weft yarns of stretch denim fabrics include spandex core-spun yarns, spandex yarns and cotton yarns intertwined (such as two 29tex cotton yarns and a 7.8tex spandex yarn slightly twisted together), and PBT elastic yarns. wait. In particular, PBT stretch yarn has the advantages of sufficient elasticity, long-lasting strength, and low cost.

Viscose fiber yarn with a linear density below 18tex is used as raw material to make rayon-like silk denim fabric. In addition to the appearance of ordinary pure cotton thin denim fabric, it also has the style of rayon fabric.

TRC denim fabrics can use viscose/cotton (R/C) blended yarn as warp yarn and polyester (T) filament or polyester/cotton (T/C) blended yarn as weft yarn.

Denim is woven from 48tex*48tex silk rotor yarn, 45tex linen/cotton (55/45) blended yarn is used as warp yarn, 125tex rabbit hair yarn (40%) and 107tex polyester air textured yarn (60 %) are interlaced as weft yarns to weave into jacquard denim fabric, which has a rich hand feel and strong wool texture.

Linen-cotton polyester denim fabrics are made of linen/cotton (55/45) blended warp yarns and linen/polyester (55/45) blended weft yarns. This blended product is rougher, more comfortable and stronger than ordinary denim fabrics. , wear resistance and other characteristics. There are also linen/cotton three-in-one crepe denim fabrics that use linen/cotton (55/45) as the warp, arranged in alternating vertical strips and interwoven with matte viscose fibers.

Using colored natural cotton as raw material, for example, Japan has developed a colored high-end denim fabric made of natural brown cotton fiber as raw material, called “flesh-colored denim fabric”. The product has a natural tone and soft luster. Adds new luster to denim.

Denim fabrics are woven with ring-spun yarns of uneven thickness as warp yarns and rotor yarns as weft yarns. They have a retro-antique tendency of “advocating classics and returning to nature” and are called “ancient denim fabrics”. Or all the warp and weft yarns are made of rotor yarns with pattern effects, and slub yarns are mixed into the normal warp yarns in a certain proportion to make slub denim fabrics. The fabric style retains the unique roughness, free and easy style of the original denim fabrics. texture, and also has a special “raindrop-like” effect, which is very popular in Europe.

Others use wild fibers (Apocynum, etc.) as raw materials.

2. Raw yarn requirements

(1) Raw yarn structure

Raw yarn spun by rotor spinning has won the favor of the denim fabric production industry for its superior performance, gradually replacing ring yarn, and Has achieved great development.

1. Structural characteristics of rotor yarn

(1) The fibers are divided into two parts: the yarn core and the outer layer. The yarn core is arranged more closely, and the outer layer of fibers is relatively loose.

(2) The fiber shape in the yarn is complex and the yarn structure is uneven.

2. Performance of rotor yarn

(1) Good uniformity, manifested by low unevenness, few details, thick spots and neps.

(2) The strength is low, but the coefficient of variation is small and the elongation is large.

(3) Good wear resistance.

(4) Good fluffiness and plump structure.

(5) Strong fatigue resistance.

(6) There is less hairiness, but the uneven hairiness is serious.

(7) The dyeing has good hygroscopicity (especially the ring dyeing effect is good).

(2) Raw yarn requirements

1. Rotor yarn quality requirements

(1) Even evenness (including long segments and short segments).

(2) There should be less confusion.

(3) It has certain strength and elasticity.

(4) No yarn defects.

(5) Few knots.

Denim fabrics have higher requirements for yarn evenness, especially high-end denim fabrics. Uneven evenness and slub yarn defects in the original yarn not only affect the strength unevenness of the warp and weft yarns, but also affect the fabric style and appearance quality of the denim fabric. In particular, sliver and slub defects on the weft yarn pose a greater threat to the appearance quality of the finished product. As for the evenness and slubs on the warp yarns, generally mild unevenness has little impact on the appearance quality of the product. Therefore, the evenness level of the warp yarns can be lower than the requirements of the weft yarns.

The knots and hairiness on the warp yarns have a greater impact on dyeing; excessive knots and hairiness on the weft yarns will also affect the appearance quality of the cloth, especially neps and hairiness, which will cause white stars on the cloth. Resulting in a large number of downgrades.

The production process of denim fabric warp yarn is characterized by a long process. If the yarn does not have sufficient strength and elasticity, it will cause a large amount of unexpected elongation or even breakage, seriously affecting the smooth progress of each production process. In addition, during the weaving process, a larger upper machine tension is generally used, which also requires the warp yarns to have higher strength and excellent elasticity.

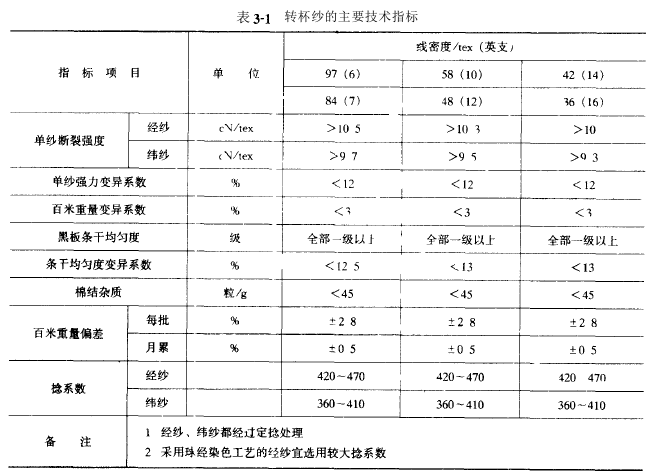

Denim fabrics are mostly made of thick special yarns, and the knots in the original yarn often protrude from the fabric surface, causing obvious knot defects. Although weft yarn knots are not as obvious and easily exposed as warp yarn knots and affect the appearance quality of the finished product, too many knots will cause scattered defects on the cloth surface. The specific requirements for rotor yarn are shown in Table 3-1.

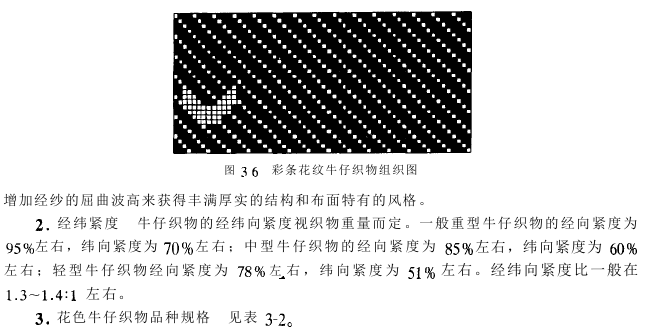

AAAWQ32RDRGFJ