Silk is known as the queen of fibers, which shows that it has many excellent properties. The goal of artificial silk is to use artificial means to make the fiber have the excellent characteristics of real silk.

To this end, we should first understand the structural performance characteristics of silk.

1. Structure and properties of silk

Silk is a protein fiber, which is made from silkworm cocoons. It is the only long fiber among natural fibers.

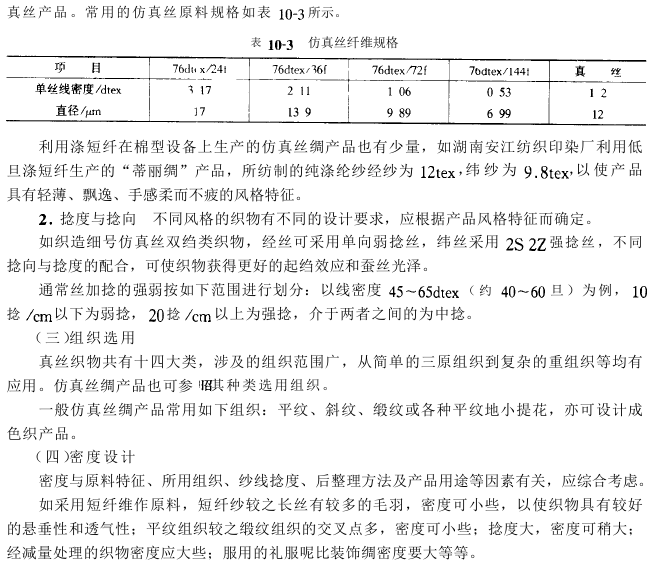

The cross section of silk is a rounded triangle, and the longitudinal surface is in the shape of an uneven branch. The soft luster and slender texture of silk mainly come from its screenshot shape: the average fiber fineness is about 1~1.5dtex, making it The fabric has excellent drape and softness; silk also has good mechanical properties, with a strength of 3.0~3.5dN/tex, an elongation of 15%~25%, and a Young’s modulus of 6860~9800N/mm2. Among natural fibers Second only to hemp: the moisture absorption rate is 10%~12%, and it has good dyeing performance and a deep color feeling.

Silk also has shortcomings, such as its poor light resistance, it is easy to yellow under sunlight and its strength is reduced; it is easy to become mildewed and moth-eaten during storage; it is easy to wrinkle and produce sweat stains and watermarks during wearing.

2. Development of imitation silk technology

Silk fabric has beautiful appearance, pearl-like soft luster, vivid hair color effect, soft hand feel, smooth style, elegant silk sound and comfortable wearing, and has become a model for people to imitate. example. However, its shortcomings have inhibited people’s demand for silk fabrics and also affected the development of the silk industry.

In recent decades, chemical fibers synthesized from polymer monomers have entered the textile raw material market in large quantities. Because of its rich raw materials and low price, developing silk-style products (i.e. chemical fiber imitation silk products) while maintaining its excellent physical and mechanical properties can not only greatly improve the performance of chemical fibers, but also open up a broad field for clothing fabrics. of heaven and earth.

(1) The development history of chemical fiber simulated silk products

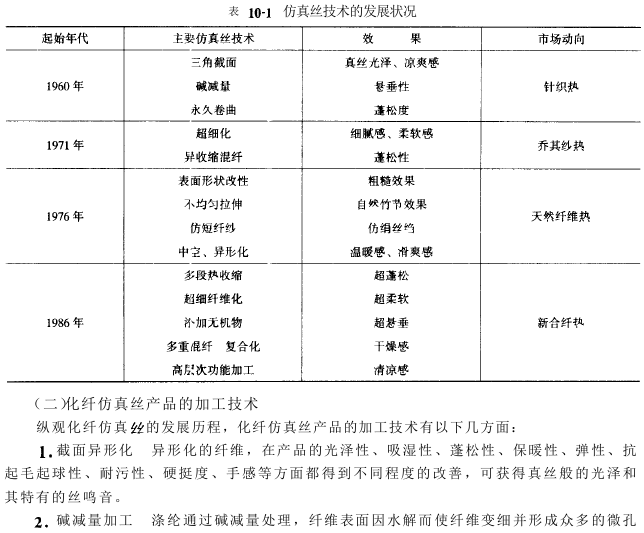

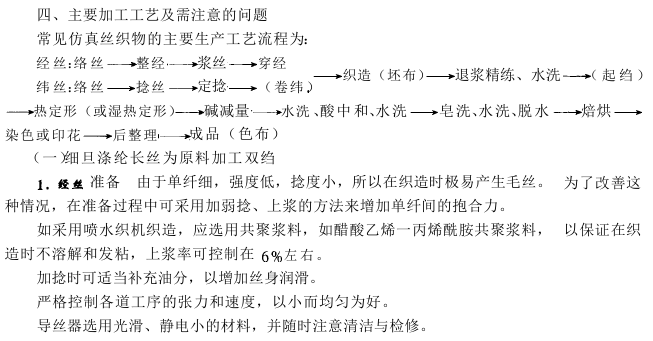

Since 1960, some foreign fiber manufacturers have begun research on chemical fiber simulated silk products. After decades of exploration, fruitful results have been achieved, and a variety of chemical fiber imitation silk products have emerged on the international market. Foreign chemical fiber imitation silk products have gone through three stages and have now entered the fourth stage of development. The development process of imitation silk is shown in Table 10-1.

AAA functional fabric network DBGRTHRTH