Natural linen fabric is rough, crisp, and breathable. It has unique advantages and enjoys a high reputation in domestic and foreign markets. However, due to the limitations of pure hemp raw materials, using other raw materials to replace hemp fiber and developing and designing imitation linen fabrics is one of the topics studied by designers in the textile industry.

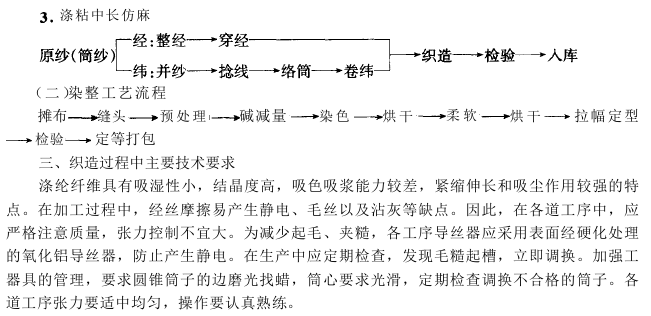

1. Design of main structural parameters of chemical fiber imitation linen fabric

(1) Selection of raw materials

To develop fabrics that fully reflect the effects of linen fabrics, raw material selection is particularly important.

1. Structural characteristics of hemp fibers. Most of the longitudinal surfaces of hemp fibers are straight, with horizontal knots and vertical lines. The single fibers are shorter than cotton. Spinning must be carried out under semi-degumming conditions, so the yarn count is thicker and even. The unevenness is high and appears in a bamboo shape. Therefore, raw materials such as polyester low elastic yarn, polyester slub yarn, polyester irregular draft yarn (physical and chemical yarn, two-color yarn), polyester slub yarn, polyester knot yarn and other raw materials are selected. Their appearance is close to that of linen fiber yarn, and the effect of imitating linen is ideal.

2. The hemp effect after dyeing and finishing. Since hemp fiber only contains 60% to 80% cellulose and hemicellulose, it contains more lignin, pectin, fat, waxy ash and sugar than cotton. Material, its dyeing is more difficult than cotton fiber, and its level dyeing properties are also worse than cotton fiber. Most of them are dyed in light colors, and the appearance shows a grainy effect after post-processing. Therefore, the following raw materials can be used: a combination of raw liquid yarn and ordinary yarn; a combination of ordinary polyester yarn, polyester modified yarn, and special-shaped yarn; a combination of polyester and acrylic, nylon, polypropylene, etc. or composite yarn; polyester DTY yarn and FDT yarn or A combination of FDT wire. The hemp grain effect produced by the twist dyeing process gives it a rough appearance, thereby achieving a hemp-like effect.

3. The fineness and cross-sectional shape of imitating hemp raw silk. When polyester filament imitates hemp, the linear density of the raw silk is generally 135~300 denier, and the number of single filaments of silk fibroin is 24~48F; the cross-sectional shape is six-leaf or eight-leaf. Other special-shaped silk.

AAA functional fabric network SVSGHRUTO