Waterproof and breathableTPU Composite functional fabric

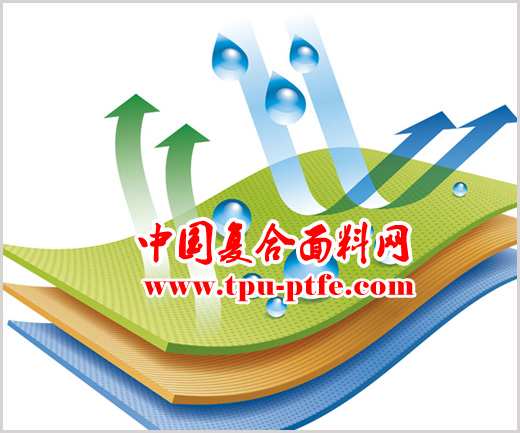

One. Overview: The waterproof and breathable membrane is made of polymer elastomerTPU as raw material, which has good elasticity and high strength. In terms of waterproof properties, although its thickness is extremely thin (0.012M/M-0.025M/M), it has physical properties unmatched by other materials (it can withstand water pressure above 10000MMH2O). In addition, high-tech technology is used to introduce a hydrophilic group into the material, so that the film not only has high waterproof performance, but also has excellent moisture permeability (human sweat can freely penetrate between the films) and can absorb the water generated by sweating during exercise. The steam is quickly eliminated from the body, so that you will not feel stuffy when wearing it, and it can properly regulate body temperature and keep the body dry. The breakthrough of this function, combined with the laminating processing technology of textiles, greatly enhances the added value of textiles. It overcomes many defects of PVC and PU leather and is now widely used in snow coats, windbreakers, cold jackets, gloves, hats, shoes, busts, sofas, toys, strollers, seat cushions, etc. In addition, it has good cold resistance It is excellent, environmentally friendly, non-toxic, recyclable and decomposable, making waterproof and moisture-permeable membranes the mainstream material in the 21st century.

2. Properties

Cold resistance: below -30℃;

. Does not contain plastic agent, no oil spit;

3. The molecular structure is simple (carbon C, hydrogen H, oxygen O, nitrogen N) and there is no air pollution when burning in the incinerator Problem: The material is exposed to moisture and microorganisms when buried in the soil, and will naturally decompose in 3-5 years.

Three. Waterproof and breathable performance

High permeability, moisture permeability: ASTME96BWG/M2X24HR>6000, waterproofness

. Medium permeability, moisture permeability: ASTME96BWG/M2X24HR>3000, waterproof degree JIS1092MMH2O>10000

3. Low permeability, moisture permeability: ASTME96BWG/ M2X24HR6000, Waterproof

.Medium permeability, moisture permeability: ASTME96BWG/M2X24HR>3000, water resistance JIS1092MMH2O>10000

3. Low permeability, moisture permeability:

Medium permeability, moisture permeability: ASTME96BWG/M2X24HR>3000, waterproof degree JIS1092MMH2O >10000

3. Low permeability, moisture permeability: ASTME96BWG/M2X24HR3000, waterproof degree JIS1092MMH2O>10000 3. Low permeability, moisture permeability: ASTME96BWG/M2X24HR10000

3. Low permeability, moisture permeability:Five. Application

Shoe materials: sports shoe trademarks, upper decorations, air cushions, outsole decorations, shoe material waterproof fabric lamination, etc.

Clothing accessories: transparent elastic bands, bra fluid bags, chlorine bags, invisible shoulder straps, waterstops, waterproof and breathable fabric lamination for ready-made garments, etc.;

Fabric: waterproof and breathable fabric, high-strength laminating fabric (used for massage air beds, aviation life jackets, chest tattoos, military water bags, etc.);

Sports equipment: balls, scooters, sleds, snow boots, camping products, water supplies, ski gloves, aprons, electronic products, medical equipment, automobile industry, etc.

Six. Film thickness range: 0.015MM-6.0MM Material: polyester and polyether

Seven. Note:

. The laminating temperature depends on the nature of the adhesive used (such as water-based or solvent-based). If the temperature is too high, it will produce adhesive that cannot be detected by the naked eye. Micropores lead to reduced waterproofness (water pressure resistance);

. The following washing methods will cause the deterioration of the film, please explain to the customer:

(1) It can be washed in a washing machine, but the washing temperature should not exceed 60℃

(2) It can be dried in a dryer, but please use a low setting and make sure the detergent has been rinsed off;

(3) It is not recommended to use any organic solvents Dry cleaning;

(4) Bleach, disinfectant or a small amount of detergent will cause the physical strength of the moisture-permeable membrane to decrease;

(5) You can use a hot iron for low-temperature ironing. When ironing, you need to place a layer of cloth on top and bottom of the fabric

.The moisture permeability is reduced after being bonded to the fabric. s1GnNYP0d