Advanced polymer materials – Aramid fiber

Advanced polymer materials

01

Advanced polymer materials refer to relatively unique physical and chemical properties that are suitable for use in special fields or specific environments. Various new polymer synthetic materials or traditional polymers that are used under the environment, are energy-saving and environmentally friendly, a new generation of new energy, biotechnology, information technology, high-end equipment manufacturing and other strategic emerging industries that are urgently needed for the development of strategic emerging industries such as national economy and people’s livelihood and are in relatively short supply in the market. Special varieties of materials. According to the structure or performance characteristics of the materials, advanced materials are divided into four sub-fields: special synthetic rubber, high-end engineering plastics, special synthetic fibers and other functional polymer materials.

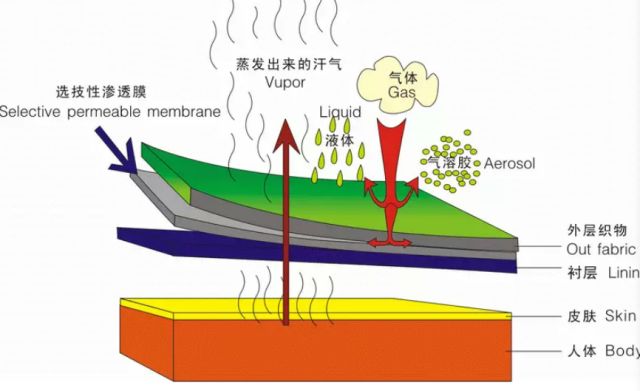

Special synthetic fibers are mainly divided into five categories according to their properties: 1. Strong corrosion-resistant fibers, which refer to fluorine-containing fibers represented by polytetrafluoroethylene fibers; 2. High-temperature-resistant fibers, which refer to long-term use Fibers with temperatures above 180°C include poly(m-phenylene isophthalamide) fiber (meta-aramid), which has a strength retention rate of 65% when heated at 260°C for 1,000 hours. It is the standard for organic high-temperature-resistant fibers. The other type is thermoplastic polyphenylene sulfide fiber, which has better heat resistance and strong corrosion resistance than the former; 3. Flame-resistant fiber refers to non-flammable fibers with chemical structures such as fused rings, three-way cross-linking or metal chelation. Fiber, representative varieties include melamine fiber and phenolic fiber; 4. High-strength and high-modulus fiber, generally refers to fibers with a strength above 18cN/dtex and a modulus of at least 400cN/dtex. Most of them have heat resistance, and their representative varieties include polyethylene fiber. Para-phenylene terephthalamide fiber (para-aramid), ultra-high molecular weight polyethylene fiber, carbon fiber; 5. Functional fiber refers to fiber with special functions. Its representative varieties include hollow fiber separation membrane, activated carbon fiber, Plastic optical fibers, biodegradable fibers and nanofibers. [1]

Advanced polymer materials

02

Here we mainly introduce aramid fiber, which mainly has two properties: poly-m-phenylene isophthalamide fiber (meta-aramid) and poly-p-phenylene terephthalamide fiber (para-aramid). Good fiber.

Aramid 1313 (meta-aramid) was first successfully developed by DuPont in the United States and achieved industrial production in 1967. The most outstanding feature of aramid 1313 is its good high temperature resistance. It can be used for a long time at a high temperature of 220 ℃ without aging. Its electrical and mechanical properties can remain effective for 10 years, and its dimensional stability is excellent. The thermal shrinkage rate is only 1% at around 300°C. It will not shrink, embrittle, soften or melt even after being exposed to a high temperature of 300°C for a short period of time. It only begins to decompose at strong temperatures above 370°C and begins to carbonize at around 400°C. . Such high thermal stability is unique among current organic heat-resistant fibers.

Because of the special characteristics of high molecular polymerization and high strength, natural aramid 1313 fiber has poor dyeing performance and poor color fastness after dyeing, which limits the aramid fiber to a certain extent. Application of 1313 fiber in high-performance protective clothing. Faced with this problem, Chaomeisi New Materials Co., Ltd. overcame the difficulties and independently developed the solution-dyed aramid 1313 fiber technology based on the natural color aramid 1313 fiber. The liquid-dyed aramid 1313 fiber not only maintains the performance of the natural aramid 1313 fiber, but also has bright, beautiful and rich color series, further expanding the application of aramid 1313 fiber in the field of flame retardant protection. At present, Supermax aramid fiber has been widely used in many industries. [2]

Aramid 1414 (para-aramid) looks golden yellow and looks like shiny metal threads. It is actually a liquid crystal polymer composed of long rigid molecules. Because its molecular chains are highly oriented along the length direction and have extremely strong inter-chain bonding forces, it gives the fiber unprecedented high strength, high modulus and high temperature resistance. The discovery of aramid 1414 is considered an important milestone in the development of the materials community. Aramid 1414 has extremely high strength, which is 5-6 times that of high-quality steel, its modulus is 2-3 times that of steel or glass fiber, its toughness is 2 times that of steel, and its weight is only 1/5 of steel. Aramid 1414 has an extremely wide continuous use temperature range and can operate normally for a long time in the range of -196-204 ℃. The shrinkage rate at 150 ℃ is 0, and it does not decompose or melt at a high temperature of 560 ℃. Its heat resistance is better than that of aromatic 1313, and it has good insulation and corrosion resistance. It has a long life cycle, so it wins the title of “synthetic product”. “Steel Wire”. Aramid 1414 was first used in cutting-edge fields such as national defense and military industry. In order to meet the needs of modern warfare and counter-terrorism, the military and police of the United States, Russia, Britain, Germany, France, Israel, Italy and many other countries have developed body-proof vests, bullet-proof helmets, stab-proof and cutting-proof suits, explosive disposal suits, high-strength parachutes, and bullet-proof vehicles. Aramid 1414 is widely used in body and armor plates. In addition to the military field, aramid 1414 has been widely used in aerospace, electromechanical, construction, automobiles, marine aquatic products, sporting goods, etc. as a high-tech fiber material. All aspects of the national economy.

Advanced polymer materials

03

With its excellent performance, aramid fiber is widely used in national defense, aerospace, construction, transportation and other fields. With the development of new energy vehicles, 5G communications and other countries With the development of strategic emerging fields, aramid fiber will also usher in huge development opportunities. The polymerization production processes of aramid fiber used at home and abroad include low-temperature polymerization, emulsion polymerization, interfacial polymerization, etc., but due to the limitations of industrialization and continuous production, Impact, the currently commonly used processes are mostly low-temperature polymerization. In recent years, as microchannel reactors have become more and more widely used in industrial production, microchannel reactors have gradually begun to be applied and promoted in aramid production. . It is foreseeable that the production of aramid fiber will become more environmentally friendly, energy-saving, safe and efficient in the future