PU coating’s film-forming basis classification, finishing methods and application overview

PU coating agent itself has certain adhesion, and it can be applied on PTFE film, knitted fabric On the surface of cloth, polyester and other substrates, functional composite coating materials can be obtained after a series of complex chemical processes, adding a variety of unique properties such as waterproof, breathable, flame retardant, etc. to the original substrate. Compared with common coating agents such as PVC, PA, and synthetic rubber, PU can obtain diversified products by adjusting the connection methods and quantities of different blocks and adding functional blocks, and it is also wear-resistant, cold-resistant, It has the advantages of high toughness and strong adhesion, and has become a commonly used coating agent for fabrics. By compounding with other fabrics, it can be prepared into high-performance space suits, radiation protection suits, anti-virus suits, pressure equalizing suits for live operations, etc., and has a wide range of uses in the field of protection.

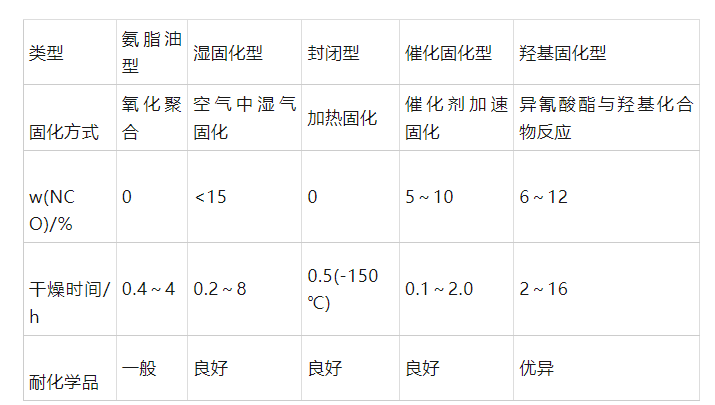

PU coating agents can be divided into five categories according to the film-forming mechanism: ammonia oil type, moisture curing type, blocked type, catalytic curing type, and hydroxyl curing type.

Type Urethane oil type Moisture curing type Closed type Catalytic curing type Hydroxy curing type

Curing method: oxidation polymerization, moisture curing in air, heating and curing catalyst to accelerate curing reaction between isocyanate and hydroxyl compound

w(NCO)/% 0 <15 0 5~10 6~12

Drying time/h 0.4~4 0.2~8 0.5(-150 ℃) 0.1~2.0 2~16

Chemical resistance is generally good, good, excellent, excellent

Moisture-curing PU has the advantages of simple operation, thorough curing, and excellent mechanical properties, and is widely used. After the PU coating agent is applied to the surface of the base film while it is hot, as the solvent evaporates and the temperature cools below the melting point, the amorphous thermoplastic segments gradually aggregate, causing the fluidity of the system to be lost, the bonding strength to increase, and the PU to solidify. Film formation. However, for moisture-curing PU, the free NCO in the PU coating agent can react with the water vapor in the air and the amino groups and hydroxyl groups on the surface of the base film, further curing and cross-linking, and the formed PU coating has both thermoplastic segments aggregated to form Physical cross-linking, and chemical cross-linking formed by NCO groups and water vapor or other active hydrogen. When chemical cross-linking is completed, the PU coating will produce a bridging effect and form a cross-linked network structure that cannot be melted even under heating conditions. This reaction is irreversible and effectively improves the adhesion, solvent resistance, water resistance, low temperature resistance and other properties of the PU coating.

Coating finishing refers to evenly applying a polymer coating agent that can form a film on the surface of the base film, and through subsequent processes, the coating agent forms a film, changing the appearance style of the base film surface and adding functionality. Sexual surface finishing technology. Different from the traditional fabric padding finishing technology, the coating finishing method mainly applies the coating agent to the surface of the fabric without penetrating into the fabric. It can be coated on one side or both sides. In addition, PU coating There are many types of layer agents, which can be adjusted and modified as needed. Moreover, coating finishing has low requirements on the base fabric. As long as the base fabric reaches a certain warp and weft density, natural fibers, synthetic fibers, and blended fabrics can be used as the base fabric. The coating finishing methods mainly include dry film forming, wet film forming, transfer film forming, hot melt film forming, adhesive film forming, etc.

Polyurethane coating agent is a high-performance coating agent that can be processed and compounded with other fabrics to form clothing fabrics with different functions and characteristics. Polyurethane has been widely used because of its excellent performance. Used in protective materials, it plays an important role. Among them, the development and application of functional polyurethane that is waterproof, breathable, and resistant to chemical corrosion is of great significance to improving the comfort, lightweight and protective performance of protective clothing. It is also one of the hot topics studied by scientific researchers in the current field of protection. one. In the future, polyurethane chemistry with resins and isocyanates as the core can provide the best, most economical and most flexible solutions in the field of protection.