Composite materialsTerminology popularization

You What does it do? composite materials.

Oh, what is composite material?

What is fiberglass?

Glass fiber, carbon fiber, resin… What are these?

Do you often encounter such curious babies, or do you have the same problem? of confusion. Today I will give you a popular science lesson so that you can not only know but also speak many professional terms about composite materials.

If something can be solved in one sentence, we will never hesitate.

Composite materials

When it comes to composite materials, people who make composite materials We all know it, but if you really want to sum it up in one sentence, it may not be comprehensive. The so-called composite material refers to a material with new properties composed of two or more materials with different properties through physical or chemical methods on a macro (micro) basis.

Although it is only one sentence, the amount of information is still quite large. A simple understanding is that various materials complement each other in terms of performance, creating a synergistic effect, so that the overall performance of composite materials is better than that of the original component materials and meets various different requirements. The simplest example, concrete is also a composite material.

GRP

Glass and steel, it seems that the two are not objects of the same level in terms of strength, how can they be related together. FRP is renamed glass fiber reinforced plastics, commonly known as FRP (Fiber Reinforced Plastics), which is fiber reinforced composite plastics. According to the different fibers used, they are divided into glass fiber reinforced composite plastics (GFRP), carbon fiber reinforced composite plastics (CFRP), boron fiber reinforced composite plastics, etc. It is a composite material that uses glass fiber and its products (glass cloth, tape, felt, yarn, etc.) as reinforcing materials and synthetic resin as the matrix material. The mechanical properties of this kind of composite material are comparable to those of steel, so it is called fiberglass. In fact, this is a popular name in our country and belongs to Chinese characteristics.

Glass fiber

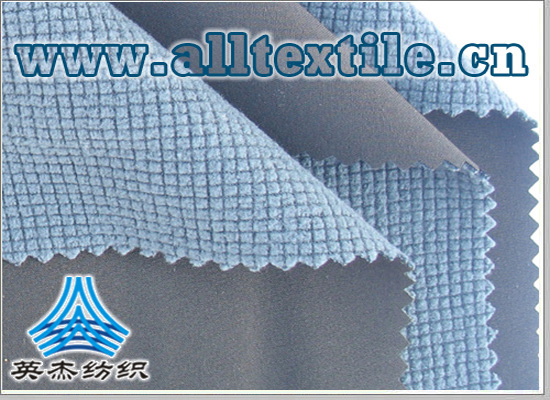

Glass fiber (fiberglass or Glass fiber) is a An inorganic non-metallic material, made of ore (mainly composed of silica) or glass spheres, which are melted at high temperature and drawn into single filaments with a diameter of several microns to more than twenty microns, and then braided into raw filaments. The raw silk can be processed into various glass fiber products, including common chopped strand mats, checkered cloths, axial cloths, composite mats, etc.

Carbon fiber

Carbon fiber (carbon fiber) refers to inorganic polymer fibers with a carbon content higher than 90%, among which those with a carbon content higher than 99% are called graphite fiber. The current production process is mainly made of organic fibers through four processes: fiber spinning, pre-oxidation, carbonization, and graphitization. According to the fiber base material, it is divided into polyacrylonitrile (PAN)-based carbon fiber, pitch-based carbon fiber, and viscose-based carbon fiber. , phenolic-based carbon fiber, vapor-grown carbon fiber, etc.

Industrial production of carbon fiber can be divided into polyacrylonitrile (PAN) based based on raw material routes There are three major categories of carbon fiber, pitch-based carbon fiber and viscose-based carbon fiber, but the first two types of carbon fiber are mainly produced. As the production process of PAN-based carbon fiber is simpler than other methods, its output accounts for more than 90% of the total global carbon fiber output. <br style='font-family: "sans serif", tahoma, verdana,A substance that is used in small amounts.

When it comes to curing agents and accelerators, safety issues must be emphasized. The curing agent is highly corrosive, so protective measures must be taken to avoid direct contact with the human body. In addition, mixing with resin or gel coat-specific accelerators may cause fire or even explosion. Therefore, in order to avoid accidents, the two must be stored separately. When adding to resin or gel coat, be sure to add accelerator first, stir evenly, and then add curing agent. (This point needs to be remembered, it is related to personal safety)

Release agent

Release agent is an interface coating used on the surfaces of two objects that are easy to adhere to each other. layer, which can make the surface of an object easy to detach, smooth and clean. To understand it simply, it is a substance that can smoothly separate products from the mold. Common types of release agents include inorganic substances, organic substances and polymers.

Commonly used release agents in FRP production include solid wax and semi-permanent release water etc.

Sandwich material

The main sandwich materials used in composite sandwich structures are: rigid foam, honeycomb and balsa wood. Its main function is to improve product rigidity and reduce weight. Generally made into a sandwich structure.

Rigid foam mainly includes polyvinyl chloride (PVC) and polyurethane (PU) , polyetherimide (PEI) and acrylonitrile-styrene (SAN or AS), polymethacrylimide (PMI), foamed polyester (PET), etc.

Honeycomb sandwich materials include glass cloth honeycomb, NOMEX honeycomb, cotton cloth honeycomb, and aluminum Honeycomb etc. The honeycomb sandwich structure has high strength and good rigidity, but the honeycomb has an open-cell structure, and the bonding area with the upper and lower panels is small, and the bonding effect is generally not as good as that of foam.

Balsa sandwich material is a natural product. The balsa sandwich common in the market is mainly produced in plantations in South America. Due to the climate The reason is that balsa wood grows very fast locally, so it is much lighter than ordinary wood, and its fibers have good strength and toughness, making it particularly suitable for composite sandwich structures.

Autoclave

Hot Air Autoelave or Atitoelave for short is a A kind of process equipment targeting the characteristics of polymer matrix composite material molding process. It can provide uniform temperature and uniform pressure at the same time to solidify polymer matrix composite materials, making the products denser and with lower porosity than traditional curing ovens.

Vacuum auxiliary materials

The so-called vacuum auxiliary materials refer to those used in the vacuum process Some auxiliary materials mainly include: vacuum bag film, isolation film, release cloth, breathable felt, flow guide net, sealing tape, pressure-sensitive tape, others (winding tube, resin tube, glue injection seat, quick connector, etc.) .

After reading the explanations of these professional terms, do you have a clearer understanding of composite materials? Let’s talk about this with you today. If there are any omissions, we will add them in subsequent articles.