TPE TPR productsThe reasons and solutions for easy paint peeling on the printing surface

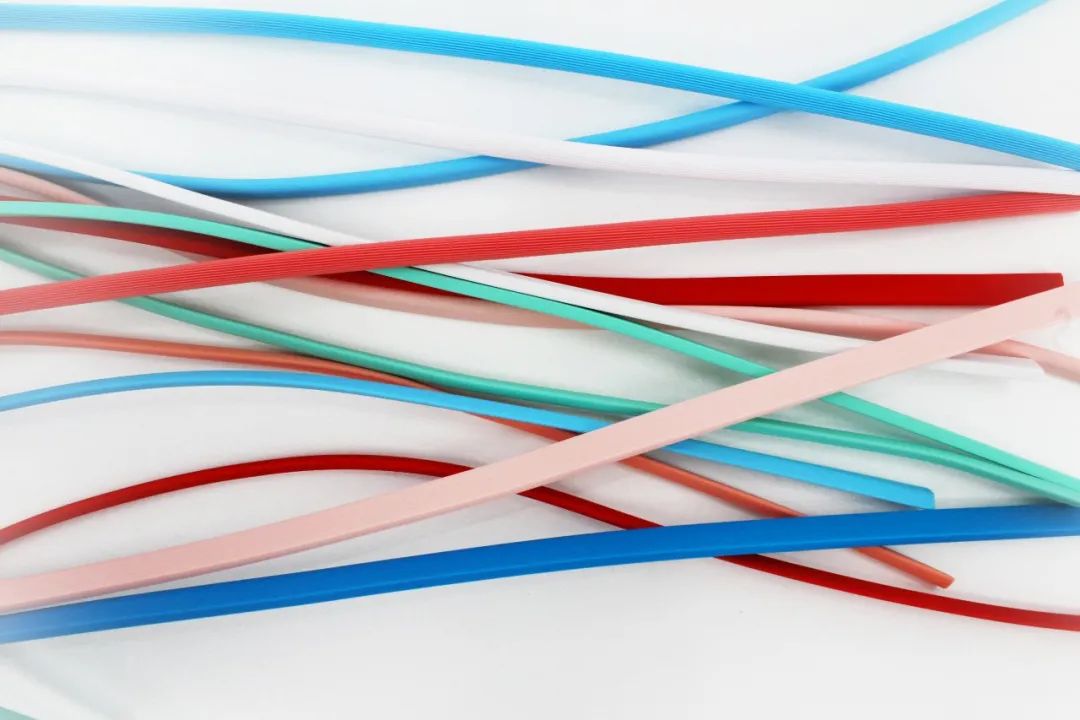

TPE and TPR materials usually have a base material blended with SBS or SEBS. Generally, the SEBS base The blend-modified elastomer is called TPE, and the blend-modified elastomer based on SBS is called TPR. TPE and TPR plastic materials are widely used in electronic equipment, wires and cables, smart watch straps, etc. Although most injection molding is used in industrial production, TPE and TPR materials are injection-molded with bright colors, and there is no need to spray paint. However, as the demand for exterior decoration increases, TPE and TPR are often surface treated through spray painting. Then came the problem of poor paint adhesion and paint peeling when spraying rubber paint and other paints.

The actual phenomenon of poor adhesion of TPE and TPR spray paint is mainly reflected in the failure of the hundred grid adhesion test Paint, the coating peels off when tested directly by hand, and paint bursts occur during tensile testing. So what is the main reason why the paint on the printing surface of TPR and TPE products is easy to peel off?

Reason 1: TPE and TPR are elastomers and will deform during tensile testing, but paint has no elasticity. When TPE, TPR and other materials are sprayed with rubber paint and then subjected to a tensile test, the rubber paint cannot be stretched to the same extent as the elastomer TPE products. When it exceeds its endurance limit, the rubber paint will crack or even fall off. The reason why the paint cracks and falls off in the tensile test is also caused by insufficient adhesion.

Reason 2: The paint and TPE and TPR materials form false adhesion, which is just a simple surface adhesion, and there is no strong bonding effect between the paint and the substrate. Paint is difficult to be compatible with TPE|TPR materials and cannot achieve intermolecular binding force. It only adheres to the surface of TPE products but cannot penetrate into the interior of the TPE material. Therefore, the adhesion between the paint and the substrate is naturally insufficient and it easily falls off.

A solution to enhance the adhesion between paint and TPE and TPR substrates:

Based on the analysis of the undesirable phenomena of TPE and TPR plastic spray paint, the first step to solve the problem of difficult oil spraying on the surface is that the paint needs to have a certain degree of toughness, so it is important to choose the right paint. Secondly, it is necessary to enhance the adhesion between TPE, TPR substrate and paint to form a firmly combined whole. The surface adhesion between paint and substrate is an important factor affecting coating quality. The method to enhance adhesion is generally through primer Shizukawa TPE treatment agent, TPR treatment agent, etc. First, activate the surface of the substrate, improve adhesion, enhance wetting ability, and at the same time combine with the paint to make the coating adhere firmly It is further enhanced and improved to solve the problem of easy peeling of paint coating.

The company is a high-tech enterprise specializing in the research and development, production, sales and service of polymer materials. , the company has been focusing on the R&D and production of thermoplastic elastomer (SBS, SEBS, TPE, TPR, TPV, TPU, TPEE, etc.) composite materials. It continuously introduces advanced production lines and like-minded people in the industry to ensure the quality of raw materials and production processes. It is stable and has laid a solid technical foundation to provide customers with the most competitive thermoplastic elastomer materials. The elastomers produced by our company have a wide range of applications. We provide users with free customized material application solutions and material price quotations. Welcome to consult us. Huize welcomes you, the consultation phone number is 0769-81885852