Polyester

1. Test content

Wash fastness, abrasion fastness, sun fastness, Twist rate, shrinkage rate, sewing tension, appearance cloth inspection, pilling

2. Testing methods

o:p>

1. Color fastness to washing

a. Take 15cmx15cm fabric, fold hems around the front, and sew it on pure cotton white lining Top;

b. Machine wash at room temperature 40°C, 50:1 for 15 minutes, clean and dry.

2. Color fastness to abrasion

a. Take The fabric is 10cm in the warp direction and 25cm in the weft direction;

b. Dry grinding: Place the cut fabric flat on the dry or wet grinder and fix it. Adjust the number of frictions to 20 times. White plain lining cloth (commonly used cotton 09 lining cloth, thinner) about 5cm The friction will affect the accuracy of the test results;

c. Wet grinding: Soak the white plain lining cloth between the two round tubes on the right side of the grinding machine ( Specially used for squeezing out water from fabrics), other procedures are the same as dry grinding.

3. Sunlight fastness

a. Take 30cmX30cm of fabric , use double layers of thicker fabric to sew in half;

b. Expose to strong sunlight for 8 to 10 hours.

4. Twist rate

Take the fabric 60cmX60cm, in the middle warp and weft direction Vertically, draw an open line of 50cm

5. Shrinkage

a. Heat shrinkage: cut the fabric vertically to 30cm : Take a fabric of 80cm

6. Sewing tension

Adjust the machine to 12 needles/3cm, sew the double-layer fabric with hidden threads, and pull it open to visually check whether the yarn will break. 7. Cloth appearance

a. Color difference: When inspecting the fabric, cut a 10cm ;

b. Defects: The cloth surface is prone to tight yarns, broken yarns, broken spandex, expansion marks, uneven dyeing, knots, colored yarns, interwoven yarns, stains, and flying flowers. , concave edges, wear marks, wrong yarns, etc., are all outside the acceptable range and require replacement;

c. Weft skew: visually inspect the warp and weft when inspecting the cloth surface. Whether the direction is perpendicular or not, the method for detecting weft inclination is: make the warp direction perpendicular, use a “T” shaped ruler perpendicular to the weft direction, start with a weft yarn extending, mark it with drawing powder from left to right, and mark it with the weft direction after completion. The distance between the parallel rulers is the oblique value.

e. Defects: When inspecting fabrics, a four-point system is used to determine the deduction standard.

When applying the four-point system for inspection, the following points should be noted:

1. The principle of deducting points for defects is that they are visible, and minor and difficult-to-detect defects will not be deducted;

2. Deductions for defects within the code shall not exceed 4 points, if it exceeds the limit, it must be cut;

3. For those with false cuts, points will also be deducted according to the above standards;

4. Any form of holes or defects that seriously affect the appearance will be deducted 4 points;

5. The inspection quantity is generally 10% of the total amount of fabric;

o:p>

6. Organization structure: (cloth mirror) the number of warp and weft yarns within 1 inch. (Thickness, tightness, weight); 7. Width: ±1cm;

8. Cloth length: The cloth length of the fabric cannot be less than the marked length;

9. Gram weight: square weight ±5%;

10. Calculation formula for defect score of 100 square yards

f. Pilling:

Put the fabric to be tested flat and fixed, and use white coarse or medium particles. Pure cotton fabric (about 20cm The fabric has the problem of pilling after use.

3. Ingredient content

100% polyester

4. Fabric color matching

a. Cut 1 meter of fabric according to the number of each vat , make a cylinder difference table;

b. Cut each cylinder into 5cm After completing the two items, use the D65 light source to compare in the color matching light box;

5. Fabric Characteristics

a. High-temperature ironing is prone to heat shrinkage, and the longer the ironing time,The greater the shrinkage;

b. After friction, pilling is easy to occur;

c. Dry/ The color fastness to wet grinding, color fastness to sunlight, cold shrinkage and cloth surface effects are all better than those of natural fibers.

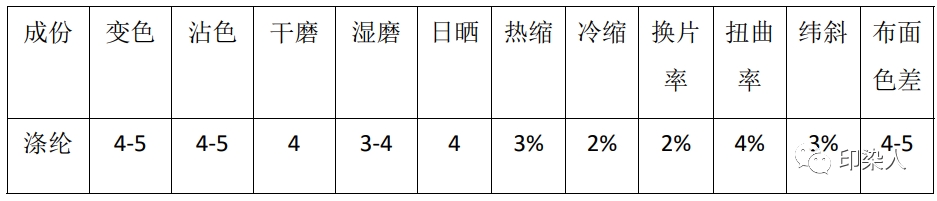

6. Standard level

7. Standard Judgment Basis

Discoloration, staining, dry grinding, wet grinding, color matching, The determination of distortion rate, light fastness and other standards are based on the “Gray Sample Card for Evaluating Staining” and “Gray Sample Card for Evaluating Discoloration”. </p