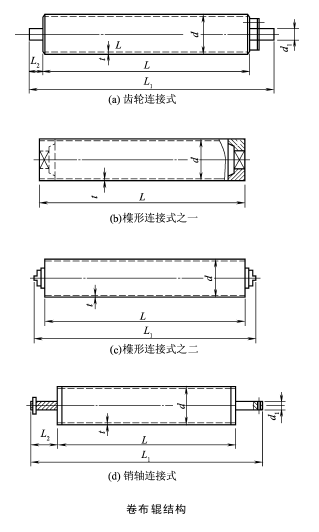

The main function of the cloth roller is to synchronously wind and transport the fabric when the loom is weaving. 1. Structure, specifications and technical requirements of the cloth rolling roller 1. Structure of the cloth rolling roller (see the figure below for the structure of the cloth rolling roller)

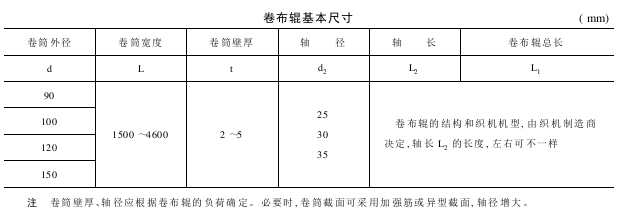

According to the transmission connection structure: (1) Gear transmission connection. (2) Tenon transmission connection. (3) Pin drive connection. 2. Specifications of the cloth rolling roller The basic dimensions of the cloth rolling roller are shown in the table below.

3. Technical requirements for cloth rolling roller (1) External surface of the roll The surrounding area must be in the form of toothed surface or roll wrapping (felt, gauze, rubber), and there should be no scratches or cracks on the surface. (2) The reel and bulkhead are firmly connected. (3) The cloth rolling roller should be straight and strong. (4) The drum should have sufficient strength and bending resistance. (5) The bulkhead should have sufficient strength and hardness. 2. Use of cloth rolling roller (1) Select the structure of cloth rolling roller according to the loom model. (2) Select the specifications of the cloth take-up roller according to the width of the loom and the fabric. (3) The roll material of the cloth roller is divided into aluminum alloy, steel pipe, and wood. With the development and improvement of aluminum alloy materials and the development of its forming technology, its powerful advantages are increasingly replacing steel pipes and wooden rolls. cylinder. (4) The bulkhead material of the cloth take-up roller can be divided into aluminum alloy, steel, and plastic. The bulkhead material of the cloth take-up roller can be selected according to the machine model and the connection structure between the loom and the cloth take-up roller. 3. Maintenance and management of the cloth rolling roller (1) The cloth rolling roller should be handled with care to avoid impact. (2) The cloth roller should be cleaned frequently to remove dirt on the surface of the roller. (3) The transmission connection part of the cloth roll should be lubricated to maintain good transmission. (4) Frequently check whether the spare parts of the cloth roller are loose, deformed, or worn, and repair and replace them in time. (5) The storage of the cloth roller should be dry, clean, moisture-proof, rust-proof and pressure-proof.

AAA composite fabric mesh DFGE465IU8GHYJ

Cloth roller composite fabric information

The main function of the cloth roller is to synchronously wind and transport the fabric when the loom is weaving. 1. Structure, specifications and technical requirements of the cloth rolling roller 1. Structure…

This article is from the Internet, does not represent Composite Fabric,bonded Fabric,Lamination Fabric position, reproduced please specify the source.https://www.yjtextile.com/archives/35600