Copper clad laminate and fiberglass cloth

Copper clad laminate andGlass fiber cloth

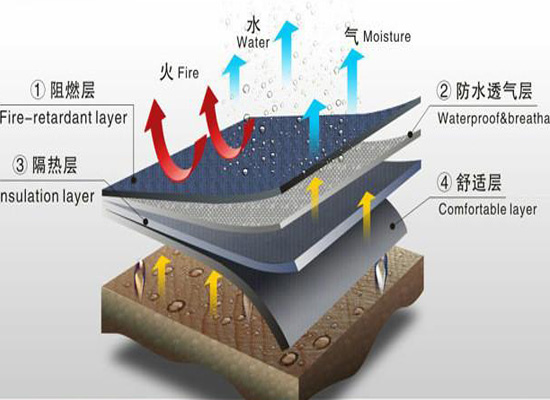

Glass fiber cloth has the characteristics of high tensile strength, good electrical insulation performance, dimensional stability, and high temperature resistance. It is a good reinforced insulation material and has been widely used in electrical insulation for decades. Fiberglass cloth is interwoven as warp and weft yarns on a loom. Compared with fiberglass paper with randomly distributed fibers, it has the advantages of high fiber density, high strength utilization, and good dimensional stability. Therefore, fiberglass cloth is the main raw material of high-quality copper-clad laminates.

Fiberglass cloth for copper-clad laminates should meet the requirements of copper-clad laminate performance, manufacturing and processing technology. The glass composition, fabric structure design, weaving process and surface treatment technology of fiberglass cloth should ensure that the fabric fully meets the application requirements in terms of technical performance, appearance and intrinsic quality.

The material essence of fiberglass cloth is glass, and its main properties are derived from the properties of glass and are related to the glass composition. Fiberglass yarn and fiberglass cloth are fiber materials processed through multiple textile processes. The structural state of glass fiber in the yarn and cloth will affect the performance of the yarn and cloth.

The weaving technology of fiberglass cloth is also an important factor in determining the quality and performance of fiberglass cloth. Surface treatment technology of fiberglass cloth can play an important role in improving the structure and performance of fiberglass cloth. The performance requirements of fiberglass cloth for copper-clad laminates depend on important technical aspects such as the glass composition of the fiberglass cloth, cloth structure, weaving technology, and surface treatment.

This patent relates to the technical field of glass fiber cloth manufacturing and discloses a method for making glass fiber cloth slices, which includes the steps: S1: Cut the glass fiber cloth sample flatly to a standard size along the warp and weft directions respectively; S2: Slowly inject a certain amount of the mixed polymethyl methacrylate solution into the mold through a dropper inserted into the mold at a predetermined oblique angle, and solidify; S3: Place the cut sample flatly on the cured polymethacrylic acid Methyl ester; S4: Mix an equal amount of polymethylmethacrylate solution with S2, inject it into the mold through a dropper inserted into the mold at a predetermined oblique angle, and solidify, and the polymethylmethacrylate solution injected twice does not exceed Mold volume; S5: Demold and take out slices. The method of this patent greatly reduces or eliminates the problems of cavities (bubbles) and poor permeability generated during the production process of slices, thereby avoiding the problem of unclear defects that occur during later running-in and observation of slices.