Lycra composite TPU, elastic, environmentally friendly and odorless

Lycra composite TPU, elastic, environmentally friendly and odorless

It is engaged in textiles, protective equipment, police equipment, clothing, shoe materials, bags, gloves, helmets, etc. It is an enterprise integrating R&D, design, production and sales, and can provide customers with a variety of raw materials and finished products.

High quality fabrics/full variety

Lycra+TPU composite

product information

Material: Very elastic fabric with good hand feel, not easy to wrinkle and deform, comfortable to wear, close-fitting and elastic, without any sense of oppression.

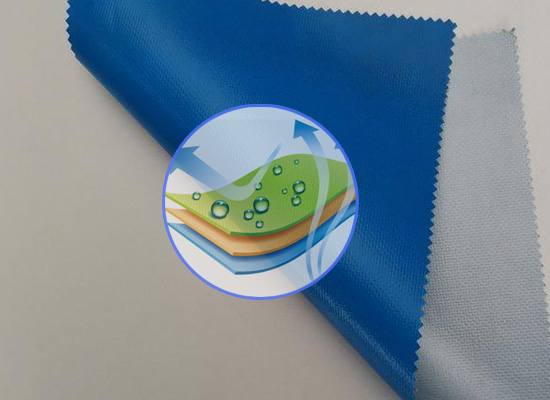

Process: The product adopts hot melt adhesive composite process, which has high peeling strength, is washable, environmentally friendly and odorless.

TPU: high transparency, medium transparency, various thicknesses can be customized according to needs

▲Can be processed and customized according to your requirements, welcome to consult

Product Features & Applications

①Soft and made of high-quality raw materials

Selected high-quality raw materials, the fabric is moisture-absorbent, breathable, soft and comfortable.

②Elasticity is added to spandex weaving

High elasticity, strong elastic recovery, and more body shaping.

③Dyeing – rich colors

It is dyed with reactive dyes and has good color fastness, washing fastness and sun protection fastness.

④Anti-wrinkle-not easy to wrinkle

Wear-resistant, wrinkle-resistant, easy to cut and versatile to use.

⑤Wide range of uses

Used in sportswear, waist bags, outdoor products, shoes, handbags, luggage and other fields.

TPU patch is a strong composite of TPU film and fabric. The combination of the two has the tensile strength of fabric and the waterproof and airtightness of TPU.

Materials required for TPU patching:

1. TPU film

2. Base fabric

TPU patch processing technology:

1. Place the fabric and TPU film on the cloth guide roller of the hot pressing laminating machine respectively, and adjust the hot pressing laminating machine to a certain temperature and pressure.

2. Put the front end of the fabric and TPU film into the coating roller of the hot pressing laminating machine for lamination.

3. Finally roll and bundle.