Application of glass fiber in biomedical field

Due to the excellent properties of glass fiber, glass fiber fabrics have the characteristics of high strength, non-hygroscopicity, and dimensional stability. Therefore, they can be used as orthopedic and restorative materials, dental materials, medical equipment, etc. in the biomedical field. Compared with traditional cotton plaster bandages, orthopedic bandages made of fiberglass fabric and various resins overcome the shortcomings of previous plaster bandages such as low strength, moisture absorption, and unstable dimensions. A composite material composed of water-soluble phosphate glass fiber and a biodegradable polymer invented by British H.D. Michael and others can be used to repair damaged tissue in patients.

A kind of glass fiber produced by biocompatible glass CPSA studied by Hokkaido University and Chiba Institute of Technology in Japan has very good plasticity. It is processed into two structures with different geometric shapes, spherical and bundled, and is combined with osteogenic protein (BMP). Implanted into animals, this can be used to study osteogenic induction factors and develop bone tissue engineering strategies. Through multiple physical tests by researchers, it has been confirmed that the CPSA (CaO-P2O5-SiO2-Al2O3) composite material has ideal biocompatibility, and CPSA glass fiber has been put into clinical use in dentistry.

Practice has proven that glass fiber membrane filters have strong adsorption and capture capabilities for leukocytes, a high leukocyte removal rate, and excellent operational stability. In addition, fiberglass has been used as a poison filter for respirators for many years. This filter material has very little resistance to air and has high bacterial filtration efficiency.

3.4 Application of glass fiber in building materials

As we all know, the outstanding characteristics of cement-based building materials are high compressive strength and low bending, tensile strength and impact resistance. With the in-depth research and development of glass fiber, the advent of alkali-resistant glass fiber has emerged. A new type of glass fiber reinforced cement material that overcomes the defects of the cement matrix. This material can not only improve the bending and tensile strength of the cement matrix, but also improve its impact strength.

FRP is a composite material that uses thermosetting or thermoplastic resin as the binding material and glass fiber yarn or glass cloth as the filling material. It combines the advantages of these two materials and has the main characteristics of light weight and high strength, as well as good heat resistance, corrosion resistance and electrical insulation. The applications of fiberglass in the construction field include lighting, sanitation, decoration, water supply and drainage, heating and ventilation, civil engineering, electrical, tooling and equipment, etc.

Fiberglass tire is another material used in the construction field. It is a fiberglass product made by wet molding of chopped glass fiber, then impregnated with polymer binder, and dried and solidified at high temperature. It has good waterproof properties. And aging and mildew resistance, dimensional stability and good processing performance. At the same time, hot melt or cold bonding methods can be used during construction, so construction throughout the year will not be affected by the climate.

3.5 Application of glass fiber in aerospace field

The aerospace field brings together the most advanced scientific and technological achievements in the world today, and is also a concentrated display of the scientific and technological level of new materials. With my country’s vigorous development in this field, high-performance glass fiber composite materials have become an indispensable material in the aerospace industry. Together with the three major metal materials of aluminum alloy, steel and titanium alloy, they have become the key to supporting the development of the aerospace industry. cornerstone.

In aviation, fiberglass composite materials are used in both civilian airliners and military aircraft. Such as inner and outer ailerons, rudders and spoilers, etc. are used. Fiber-reinforced plastics effectively reduce the mass of aircraft, increase commercial loads, and save energy. Fiber-reinforced engineering plastics are used in the cabin’s ceiling, luggage, various instrument panels, fuselage air-conditioning compartments, covers, etc., achieving the effect of being lightweight, beautiful and durable.

In the aerospace field, high-performance glass fiber composite materials are increasingly used as main load-bearing structural materials in launch vehicles and spacecraft. The fiber/epoxy composite solid engine casing manufactured by the fiber winding process is a milestone in the development history of modern composite materials. It has the properties of corrosion resistance, high temperature resistance, radiation resistance, flame retardancy, and anti-aging. The heat-proof materials on the spacecraft use a large number of fibers and high-silica-reinforced phenolic resin.

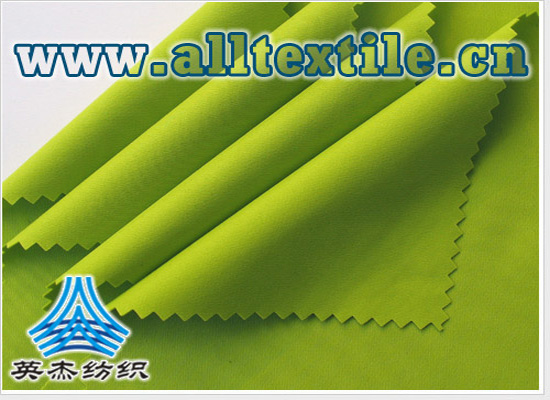

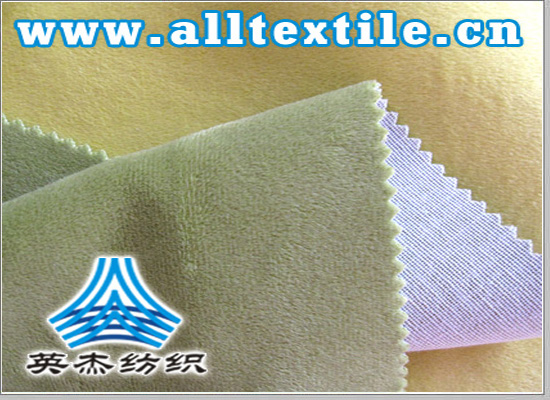

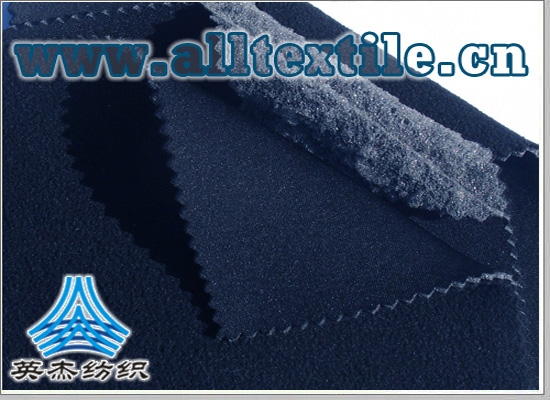

In addition, researchers chemically treated the surface of the glass fiber, effectively improving the brittleness of the glass fiber, thus producing an ultra-fine glass fiber fabric that is 7 times softer than cashmere and 14 times softer than Liang cloth. It has been successfully used in the production of space suits. In short, glass fiber material has been successfully used from my country’s Shenzhou 2 to the Shenzhou 7 manned flight.

Summary:

In recent years, with the rapid development of domestic glass fiber,my country has gradually become the largest fiberglass producer in the world, and the demand for glass is also increasing year by year. The basis for the production capacity growth of the domestic fiberglass industry is the increase in demand, which requires export sales while meeting domestic demand.