Performance characteristics of glass fiber reinforced polyurethane photovoltaic profiles

About glass fiber reinforced polyurethane profiles:

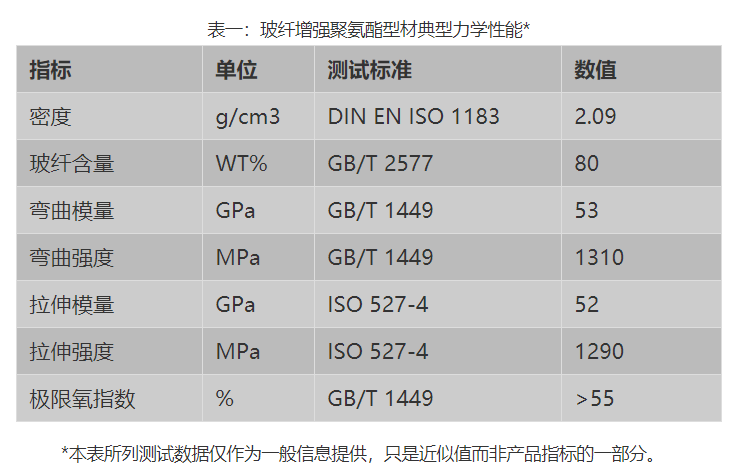

1. Mechanical properties and fire resistance of glass fiber reinforced polyurethane pultruded profiles

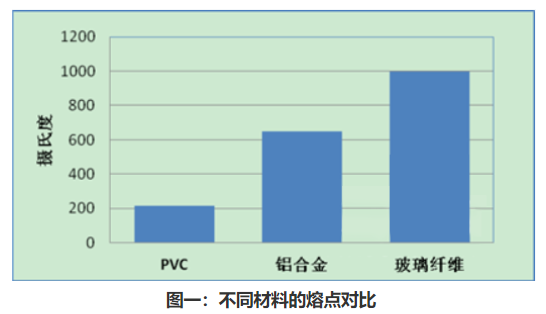

The fire resistance of glass fiber reinforced polyurethane profiles comes from the material itself. Glass fiber is an inorganic fiber with good flame retardancy and heat resistance, and its melting point is usually above 1000 degrees. Polyurethane materials are thermosetting materials. When exposed to fire, they will form a carbonized layer on the surface to prevent the flames from penetrating deep and will not melt or produce droplets. Glass fiber reinforced polyurethane composite materials are difficult to burn when exposed to fire, and the high temperature on the fire surface is difficult to conduct to the other side.

2. Technological advantages of glass fiber reinforced polyurethane materials

1) High fiber content, simple fiber structure, and superior profile performance:

§ The fiber content can reach 80%, which greatly improves the performance of the profile.

§ Reduce or even eliminate the use of fiber felt or cloth, greatly simplifying production and improving efficiency.

§ Can produce profiles with complex cross-sections and thin walls without cracking.

§ The profile surface is smooth.

2) Material performance and quality are stable and reliable:

§ The ratio of raw materials is fixed. All raw materials are tested and fixed before use to ensure product quality.

§ Automated manufacturing. All processes such as raw material proportioning, mixing, conveying, fiber soaking, traction, profile curing and molding, and cutting are completed by automatically controlled equipment to ensure the consistency of product quality.

3) Clean and environmentally friendly production:

§ Polyurethane resin contains no styrene, minimizing impact on the environment and worker health.

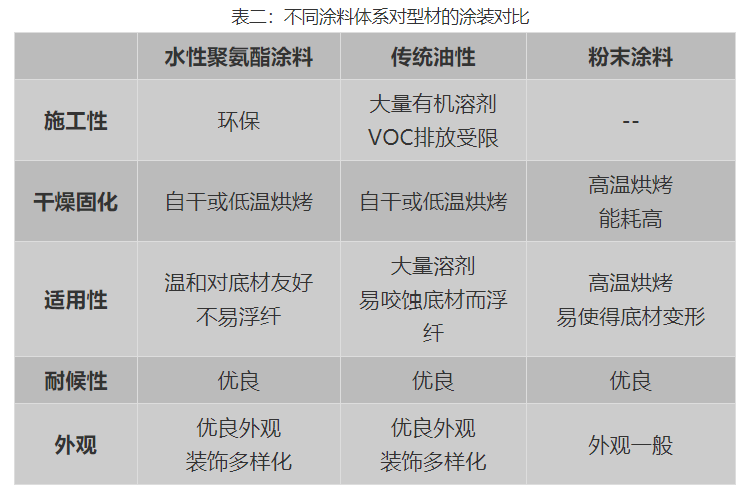

3. Surface decoration of glass fiber reinforced polyurethane profiles

Glass fiber reinforced polyurethane materials have a high fiber content. In order to meet the requirements of protection and aesthetics, a suitable coating system can be selected to coat the surface. The new generation of water-based environmentally friendly polyurethane coating developed by Deyilong’s partners is specially used for decoration and protection of the surface of glass fiber reinforced polyurethane profiles. Has the following characteristics:

§ The specific system effectively covers evenly and improves the surface flatness of glass fiber reinforced polyurethane materials.

§ Excellent adhesion properties on the surface of glass fiber reinforced polyurethane materials

§ Long-lasting protection, light/UV resistance, anti-aging

§ Color, gloss and surface effects can be flexibly selected to meet diverse needs