A highly flame-retardant breathable protective fabric and its preparation method (ramie fiber)

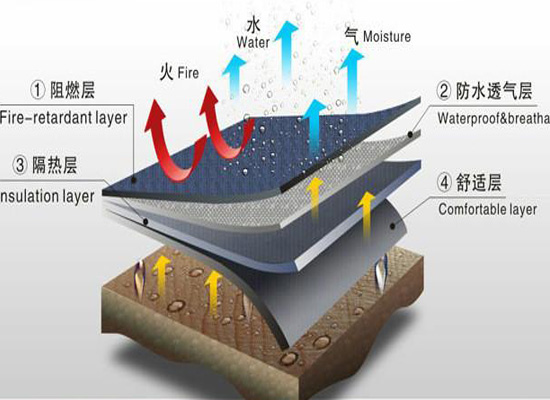

Abstract: The present invention relates to a highly flame-retardant breathable protective fabric and a preparation method thereof, and belongs to the technical field of textile fabrics. The highly flame-retardant and breathable fabric includes a base fabric and a flame-retardant layer bonded to the surface of the base fabric. The base fabric is woven from modified ramie fiber and polyester fiber. The present invention first selects modified ramie fiber with good air permeability as the main fiber to ensure the air permeability and heat dissipation performance of the base fabric, and modifies the ramie fiber to improve its elasticity, cohesion and spinnability; secondly, in order to ensure the base fabric To improve the breathability of the fabric, we chose to modify the outer layer of the base fabric on one side and graft a flame retardant layer on the outer layer of the base fabric; again, the flame retardant layer was modified on one side to improve the flame retardant layer and The bonding performance between the base fabrics; finally, the flame retardant layer contains a flame retardant, which has excellent flame retardant properties, and the flame retardant contains fluorine-containing branches, giving the flame retardant layer high flame retardant properties, water resistance, and chemical reagent resistance performance.

Claim

1. A highly flame-retardant breathable protective fabric, characterized by: comprising a base fabric and a flame-retardant layer bonded to the surface of the base fabric, the base fabric being woven from modified ramie fiber and polyester fiber; the flame-retardant layer It includes the following steps: seal one side of the flame-retardant polyester film with polyethylene tape, put the unprotected side of the single-sided protected flame-retardant polyester film into an oxidant solution, and treat it at 95°C. The unprotected side was oxidized for 7 hours to obtain a unilateral oxidation-modified flame retardant layer.

2. A highly flame-retardant breathable protective fabric according to claim 1, characterized in that: the content of modified ramie fiber in the base fabric is 75-85%, and the content of polyester fiber is 15-25%.

3. A highly flame-retardant breathable protective fabric according to claim 1, characterized in that: the modified ramie fiber includes the following steps:

A1. Place the ramie fiber in a sodium hydroxide solution with a mass fraction of 18%, react at room temperature for 3 hours, and then wash until neutral to obtain alkali-treated ramie fiber;

A2. Place the alkali-treated ramie fiber in mixed solution A and react at 55°C for 5 hours, wash with water and then with absolute ethanol, then wash with water until neutral, and dry to obtain etherified modified ramie fiber, in which the mixed solution A is composed of epichlorohydrin, 5% mass fraction sodium hydroxide solution and absolute ethanol according to 3‑4g:

50g: 3‑5mL mixed composition;

A3. Place the etherified modified ramie fiber in mixed solution B to react at 50°C for 5 hours, wash with water, absolute ethanol, and then wash with water until neutral to obtain modified ramie fiber. Mixed solution B is composed of amino-terminated polyethylene. Siloxane, sodium bicarbonate and absolute ethanol are mixed according to 0.65-0.85mol: 5-7g: 100-120mL.

4. A highly flame-retardant breathable protective fabric according to claim 1, characterized in that: the flame-retardant polyester film is made by the following steps:

After the flame-retardant polyester resin particles and the organic solvent are mixed evenly, a flame-retardant polyester solution is obtained; the flame-retardant polyester solution is electrospun, and a flame-retardant polyester film is obtained after the solution is completely spun.

5. A highly flame-retardant breathable protective fabric according to claim 4, characterized in that: the flame-retardant polyester resin particles are made by the following steps:

C1. Mix hexafluorobutyl methacrylate, phosphate monomer, 1,1,3,3-tetramethylsilane and anhydrous toluene, stir evenly, then heat to 96°C under nitrogen protection, and then Add chloroplatinic acid isopropyl alcohol solution and react for 5 hours. After post-processing, a flame retardant is obtained;

C2. Add polyester particles, flame retardant and compatibilizer into the extruder for extrusion granulation to obtain flame-retardant polyester resin particles.

6. A highly flame-retardant breathable protective fabric according to claim 5, characterized in that: the phosphate ester monomer is made by the following steps:

After mixing caged phosphate ester, acetonitrile, anhydrous aluminum trichloride and triethylamine, add allyldimethylsilyl chloride, stir at 70°C for 1.5h, then heat up and reflux for 12h to stop the reaction. Process to obtain phosphate monomer.

7. A highly flame-retardant breathable protective fabric according to claim 6, characterized in that: the caged phosphate ester, acetonitrile, anhydrous aluminum trichloride, triethylamine, allyl dimethyl chlorosilane The dosage ratio is 0.21‑0.25mol: 100‑200mL: 3‑5g: 0.35‑0.55mol: 0.1mol.

8. The preparation method of highly flame-retardant breathable protective fabric according to claim 1, characterized in that it includes the following steps:

The first step is to weave modified ramie fiber and polyester fiber into base fabric;

The second step is to bleach and dye the base fabric, remove wrinkles, and dry it to obtain the treated base fabric;

The third step is to use the flame retardant layer as the surface layer, in which the unilateral oxidation-modified surface of the flame retardant layer is used as the bonding surface, and the treated base fabric is used as the bottom layer. Use hot pressing to bond the flame retardant layer to the base fabric. Together, a highly flame retardant breathable protective fabric is obtained.

Technical field

The invention belongs to the technical field of textile fabrics, and specifically relates to a highly flame-retardant breathable protective fabric and a preparation method thereof.

Background technology

Ordinary chemical fibers, synthetic fibers and natural fibers are relatively easy to burn. In high-temperature industries such as firefighting and smelting, the powerful radiant heat energy causes ordinary clothing to quickly melt and decompose.�It burns and easily burns the operator’s skin, threatening their life safety. Flame-retardant clothing adds flame-retardant fibers to the fabric or coats the fabric with flame-retardant, which can greatly slow down the burning speed, extinguish itself immediately after moving, and the burning part is quickly carbonized without melting or dripping. Or piercing holes, giving people time to evacuate the burning scene or take off burning clothes, reducing or avoiding burns and scalding, and achieving the purpose of protection. Flame retardant clothing has therefore become one of the necessary protective products for workers working in high temperatures.

General fire-retardant fabrics are made of flame-retardant materials or have flame-retardant components added to ordinary fibers. They have a

It has certain fire resistance and is used in decorative fireproof wall coverings and firefighting clothing, but its breathability is poor and wearing comfort is poor.

Firefighters and other high-temperature workers are often exposed to flames or high temperatures. They need protective clothing or protective products in addition to

In addition to being able to withstand high temperatures, due to the violent exercise of the human body, the amount of sweat emitted by the human body is doubled, coupled with the extremely high external ambient temperature

The temperature will cause firefighters to feel a great sense of stuffiness, which will seriously affect the firefighters’ combat efficiency.

For example, Chinese patent CN105113257A discloses a waterproof, breathable, and fireproof all-polyester PU protective fabric, including a base

cloth, the surface of the base cloth is sequentially coated with a first waterproof and flame retardant coating, a second waterproof and flame retardant coating, and a third waterproof and flame retardant coating

and a fourth waterproof and flame retardant coating. In this invention, the surface of the fabric is coated with multiple layers of flame-retardant coatings, and its air permeability must be reduced.

Therefore, the present invention provides a protective fabric with good flame retardant performance and good air permeability and a preparation method thereof.