As we all know, membranes have different types of constructions, such as flat membranes, hollow fiber membranes and tubular membranes. Among them, hollow fiber membranes are a very advantageous structure due to their large surface area per unit volume (approximately ten times that of spiral wound components), self-mechanical support, good flexibility, and easy operation during component preparation. sexual characteristics. Let’s take a look at this ptfe hollow fiber membrane type membrane.

Due to the excellent hydrophobicity and anti-pollution properties of PTFE membrane materials, cheap lime is used instead of liquid alkali to adjust the pH value, which greatly Significantly reduced operating costs. The system has the advantages of low energy consumption, high ammonia nitrogen removal efficiency, long membrane life, compact device, and simple operation. However, ptfe hollow fiber membranes are also prone to problems. When the hollow fiber membrane bioreactor is running, the membrane filaments are always in a shaking state under aeration, so these hairs can easily make the membrane filaments tangle together. When the sludge concentration reaches a corresponding level, mud lumps will appear, causing the More and more membrane filaments are entangled together, which greatly reduces the membrane area of the hollow fiber filaments, causing a sharp decrease in membrane flux. Moreover, such problems are difficult to solve and usually can only be replaced.

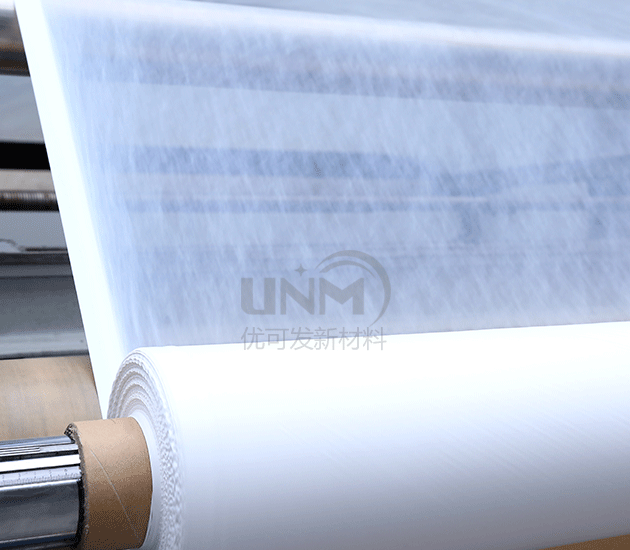

It is the manufacturer of ptfe hollow fiber membrane. This thin film is made by mixing, extruding, extruding, calendering and two-way drawing. Made with special techniques such as stretching. Due to the characteristics of ptfe fibrillation, when uniaxial stretching (i.e. longitudinal stretching) is performed, the ptfe polycrystalline aggregates begin to extend and form some fibrils. The fibrils are parallel to the stretching direction and the length of the fibrils increases. ptfe The cross-section of fibrils is wide and thin, with the largest width being about 100nm, while the small fibrils are 0. 5 ~ 1. 0nm. Interested parties can enter the store for consultation and purchase!

</p