Pollution from breeding has become a major problem affecting the rural ecological environment. Pollution from livestock and poultry breeding has become an important source of agricultural non-point source pollution, and it is urgent to solve the problem of comprehensive utilization of manure. Therefore, Nano Compost Membrane came into being.

Nano membrane aerobic fermentation composting equipment is based on static composting, adding ventilation ducts and control systems to achieve automatic aeration and temperature control, reducing odor and nitrogen loss, and providing equipment support and technical support for the development of agricultural ecological cycles. Its advantage is that it can process livestock and poultry manure nearby, avoid secondary pollution caused by long-distance transportation of manure, and can effectively prevent and control the emission of harmful substances such as odors and pathogenic bacteria. A ceremony to unveil the film-covered compost was held at the observation site. The compost after the film was removed did not have the rancid smell of traditional compost fermentation.

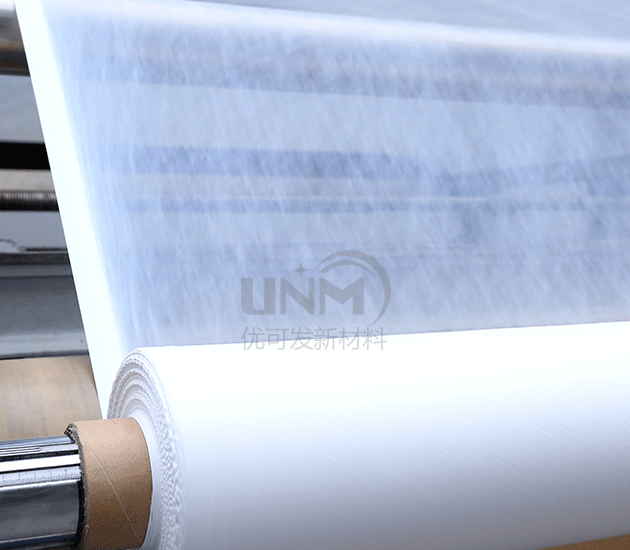

Composting fermentation technology is a very useful treatment method for the current resource utilization of livestock and poultry manure. Compost fermentation technology is a technology that uses a functional membrane as a covering for the aerobic fermentation treatment of livestock and poultry manure. The currently independently developed PTFENano Compost Membrane is the core material of this process technology. It is prepared using a biaxial stretching process. Nano Compost Membrane Use special technology to modify the properties of the PTFE membrane, and then use nanotechnology to add carbon particles into it, so that the film can isolate the volatilization of heavy metals and prevent the spread of odors.

PTFENano Compost Membrane technology has always been the core of the business, and is used in biopharmaceuticals, equipment, food and beverages, semiconductor processes, and communications It plays an indispensable role in many fields, with pore-forming capabilities ranging from 0.1μm to 1μm, providing functional solutions such as fine filtration, removal of small bacteria and viruses, hydrophobic breathability, and sound transmission. Interested parties can enter the store for consultation.

</p