1. Linear density of yarn

Determination of yarn linear density is one of the main contents of fabric design. The linear density plays a decisive role in the performance of the fabric and should be selected according to the use and characteristics of the fabric.

In fabric design, there are generally three forms of configuration of warp and weft density, namely Ttj=Ttw, Ttj>Ttw, Ttj<Ttw. In most cases, there are two forms: Ttj=Ttw and TtjTtw is also used. If the density of warp and weft threads is different, the difference should not be too large. Because the density difference between the warp and weft threads is too large, it will change the geometric structure of the fabric, change the buckling of the warp and weft yarns, change the state of the yarns on the fabric as the supporting surface, and affect the wear resistance and other wearing properties of the fabric.

2. Yarn twist

Yarn twist is related to the appearance and fastness of the fabric. When designing, certain requirements should be put forward for the yarn twist based on the characteristics of the fabric. Within the critical twist range, appropriately increasing the yarn twist can improve the strength of the fabric. However, if the twist is too high, the fabric will feel stiff and have a weak luster. Fabrics with smaller twist will have a softer feel and better luster. During the design process, different twist coefficients should be selected according to the different warp and weft yarns and fiber lengths in the fabric. Generally, the warp twist is slightly higher than the weft twist, thin fabrics have a greater twist than medium-thick fabrics, tight fabrics have a greater twist than soft fabrics, yarns with low linear density have a greater twist than yarns with high linear density, and yarns with short fiber lengths The twist is greater than the twist of yarn with long fiber length.

When the fabric is woven with strands, the twist combination of the thread and yarn has a certain impact on the strength, wear resistance, gloss and feel of the fabric.

When the ratio of twist coefficients between strands and single yarns is √2, the strands have the highest strength. When the ratio of twist coefficients is 1, the surface fibers are parallel to the axis of the strands, the yarn has the best luster, and the yarn The structure of the lines is tighter. Since some impurities have been removed from the single yarn during the twisting process, and the surface hairiness is reduced, the wear resistance, feel and gloss of the thread fabric are better than those of the yarn fabric.

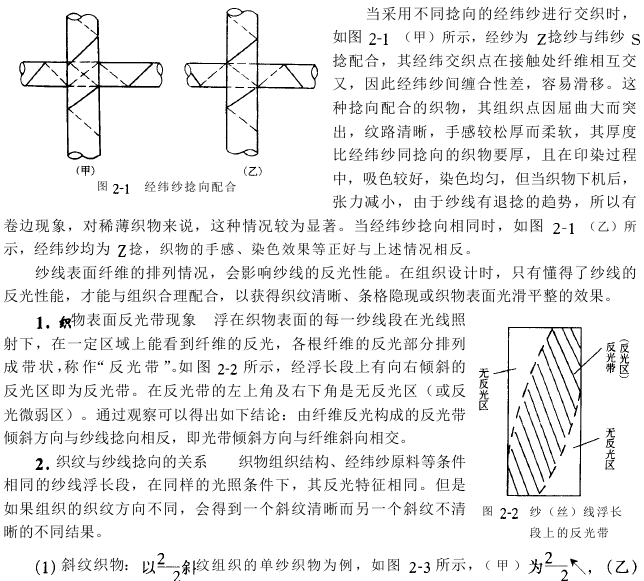

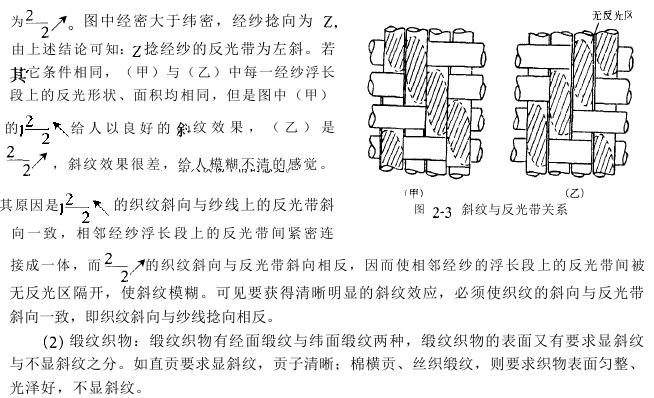

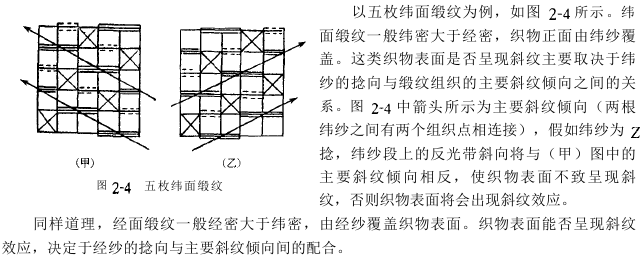

3. The twist direction of the yarn and the reflective tape on the floating section of the yarn

The twist direction of the yarn is divided into two types: Z twist (right twist) and S twist (left twist). The warp and weft yarns in the fabric are twisted. The directional cooperation has a certain impact on the feel, thickness, surface texture, etc. of the fabric. Usually there are four forms of combination of twist directions of warp and weft yarns, namely, the combination of Z-twist warp yarn and Z-twist weft yarn, S-twist warp yarn and S-twist weft yarn in the same twist direction, Z-twist warp yarn and S-twist warp yarn, S-twist warp yarn and Z-twist weft yarn. Matching with different twist directions.

AAA functional fabric networkSDFWERTEYRHF