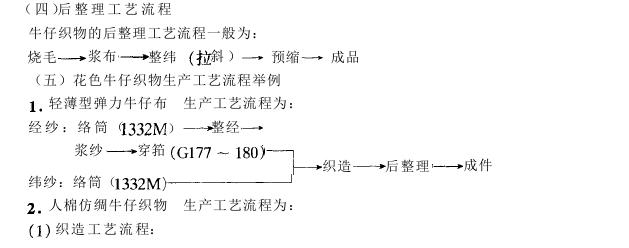

1. The production process of denim fabric

According to the warp dyeing method, the process can be divided into bundle dyeing (ball warp dyeing or rope dyeing) and production-like dyeing of sheet denim fabric.

(1) Bundle dyeing

The warp yarn process of bundle dyeing is:

Ball warping → Bundle dyeing → Warp splitting → Sizing → Drawing or warping → Weaving → Finishing

br> In this process, the dyed warp yarns are arranged twice in the process from warp dividing to sizing, thus covering up the regional color differences caused by the dyeing process, making the color of the finished product uniform and soft, and making the garments stone-ground. After processing, there will be no color bars and the quality is good. However, there are many processes, and the investment, floor space, and labor are relatively large.

(2) Flake dyeing

The warp yarn process of flake dyeing is:

Warping→Dyeing paste→Drawing or knotting→Weaving→Finishing

This process is due to the fact that in the dyeing process In the process, there are many stops and there is no double arrangement of warp yarns, so the color uniformity is difficult to control, the efficiency is low, and the consumption of indigo dye is large. But it has the characteristics of fewer processes, less damage to warp yarns, less investment, less labor and quick results. Most of the denim fabrics produced in my country adopt the sheet dyeing process.

(3) Weft yarn preparation process

There are two situations. It is woven using shuttleless looms (air-jet looms, rapier looms, etc.) and does not need to go through the weft rolling process. Weaving with a shuttle loom generally requires a weft rolling process; with direct weft weaving, the weaver does not need to roll the weft.

AAA anti-UV fabric net FSGRETEGSDFW