PTFE composite fabric performance

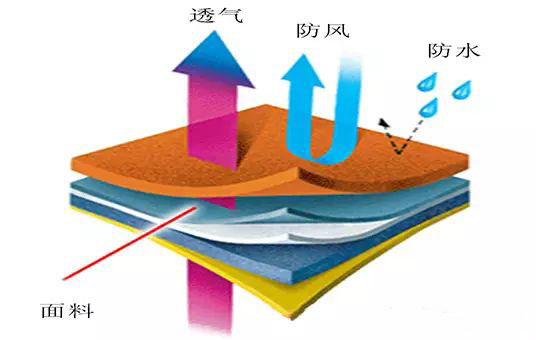

PTFE composite fabric is a functional fabric that uses a special process to compound a PTFE clothing membrane on the surface of ordinary fabrics, which is waterproof, breathable, windproof and warm. Its unique properties are:

Waterproof performance

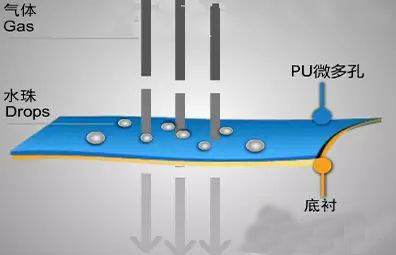

Waterproof means that water on the outside of the fabric will not penetrate the fabric and soak into the inside. PTFE laminated composite fabric is still waterproof even under 80lb/m2 pressure. When wearing this fabric, people will not feel wet even if they stand in a violent storm or sit on a wet surface. The reason why this fabric garment has such magical functions is mainly because the micropore diameter of the PTFE membrane of the main body of the fabric is 1/5000-1/20000 of the diameter of water droplets, so even small raindrops cannot pass through. The surface energy of PTFE is low, and water droplets cannot spread on the film, preventing water droplets from penetrating. [1]

Moisture permeability:

The porosity of the PTFE film is as high as 80%, the average pore diameter is 0.2µm, and the micropore diameter is 700 times larger than water vapor molecules. Steam molecules can pass freely.

Windproof performance

During the stretching process, the PTFE film forms a microporous structure with nodes connected to countless microfibers. The microfibers form pores, and the pores penetrate each other to form Unique network structure. The wind cannot pass directly, and will change direction and turn back when encountering obstacles, effectively preventing air penetration, so it has excellent windproof performance.

Thermal performance

The PTFE film has excellent moisture permeability, which can promptly transmit the steam emitted by the human body to the outside of the microclimate and prevent water vapor from condensing into liquid water. Reduce the possibility of water conducting heat. Although there are a large number of micropores on the surface of the film, wind cannot penetrate it, effectively preventing air convection. Tests have shown that in strong winds of 25m/s, the thermal insulation effect of PTFE composite fabric is 30-40% higher than that of traditional down jackets.

Nuclear, biological and chemical resistance

The PTFE film has a small pore size (average pore size 0.2µm) and blocks certain toxic gases Or the penetration of aerosols, low surface can prevent the penetration of certain toxic liquids. Coat one side of the film with a non-porous material with high water vapor flux to achieve selective penetration of water vapor and achieve complete protection. Nuclear, biological, and chemical protective clothing made of PTFE composite fabrics has multiple functions such as waterproof, moisture-permeable, windproof, and nuclear, biological, and chemical protection.

composite fabric