Application of PUR hot melt adhesive in composite fabrics and electronic products!

PUR hot melt adhesive

PUR hot melt adhesive – moisture curing reactive polyurethane hot melt adhesive

PUR (Polyurethane Reactive), the Chinese full name is wet Gas-curing reactive polyurethane hot melt adhesive. The main component is isocyanate-terminated polyurethane prepolymer. PUR’s adhesiveness and toughness (elasticity) are adjustable, and it has excellent bonding strength, temperature resistance, chemical corrosion resistance and aging resistance. Reactive hot-melt adhesive melts into a fluid under conditions that suppress chemical reactions to facilitate application; after the two adherends are laminated and cooled, the adhesive layer condenses to form a bonding effect; and then with the help of moisture present in the air The air and moisture attached to the surface of the adherend react with it and extend the chain to form a high-molecular polymer with high cohesion, which significantly improves the adhesion, heat resistance, low temperature resistance, etc. Due to its extremely high reactivity, it shows excellent adhesion to a variety of materials. In recent years, it has become one of the important varieties in the adhesive industry and is now widely used in packaging, wood processing, automobiles, textiles, electromechanical, Aerospace and other national economic fields.

PUR adhesives contain polar and chemically active urethane groups (-NHCOO-) or isocyanate groups (-NCO) in their molecular structure, and can be used with materials containing active hydrogen, such as wood, leather, and fabrics. , paper, ceramics and other porous materials and plastics, metals, glass, rubber and other smooth surface materials have excellent adhesion.

Technical parameters

Appearance milky white solid

Open time (open time 3mm thick 20℃) 60-90 seconds

Specific gravity 1.12 g /cm3

Viscosity (120℃) 11±1pa.s

Isocyanate 0.9~1.2%

Adhesive performance A1/A1 2.3±0.1Mpa

p>

Adhesive performance ABS/ABS 3.4± 0.1Mpa

Gluing temperature <155℃

Using temperature (temperature resistance after curing) -40℃~95℃

How to use

1. Heat the PUR glue at 130℃ for 40 minutes, and use Noxin Use a dedicated platen-type PUR hot-melt glue machine of 20kg (200kg) to apply glue or use a pneumatic (or manual) glue gun to squeeze the glue into the parts that need to be bonded, and the bonding can be completed in 1 minute.

2. The bonded workpiece can be trimmed after leaving it for 10 minutes to remove excess glue.

3. The finished work should be placed at 23℃ and 65% relative humidity for 24 hours before moving to the next process. Performance testing can be conducted after one week.

4. Construction should be carried out under well-ventilated conditions. Uncured glue can be wiped off with acetone. After the glue is used up, the glue machine must be cleaned with the company’s matching detergent.

Storage

PUR glue should be stored in a dry, cool place. Avoid exposure to sunlight and contact with steam, water and alcoholic solvents. Shelf life is 6 months.

Packaging

310ml aluminum alloy tube, 500g aluminum-platinum bag, 20kg/barrel.

Compared with EVA hot melt adhesive and water-based/solvent-based adhesives, PUR has the following advantages:

1. Solvent-free, one-component type. Unlike solvent-based adhesives, which require a drying process, there are no environmental pollution and poisoning problems due to solvents, and it meets environmental protection requirements. The bonding process is simple, and glue application methods such as roller coating or spraying can be used.

2. Good operability. The two adherends can be fixed in a short time, so the assembly can be quickly transferred to the next processing step to improve work efficiency.

3. Excellent resistance to heat, cold, water vapor, chemicals and solvents. Compared with the original hot melt adhesive, the listed properties and bonding strength are greatly improved due to the cross-linked structure of the reactive hot melt adhesive.

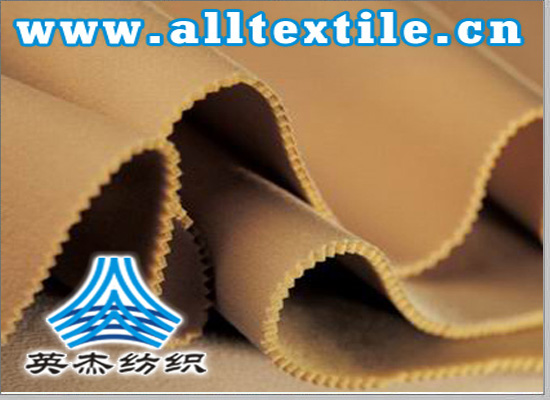

Application of PUR hot melt adhesive in composite fabrics

Current status of fabric composite adhesives

• Water-based polypropylene system adhesive (cloth and cloth stickers combination);

• Solvent-based system adhesive (cloth and film bonding);

• PUR hot melt adhesive system adhesive (cloth and film bonding);

• EVA/polyamide hot melt adhesive system (cloth to cloth lamination).

Comparison of PUR hot melt adhesive and oil glue (solvent glue)

Application of cloth film

PUR hot melt adhesive oil glue

Environmentally friendly, solvent-free and solvent-containing, highly harmful

Fast curing speed, high production efficiency requires solvent evaporation, low production efficiency

Requires less labor and requires a large number of workers

Affected by the environment and not affected by the environment

Resistant to washing 50 times at 60 degrees, and can also be washed at 90 degrees and 20 times at 60 degrees

Low amount of glue applied, large amount of glue applied

Good hand feel

Application of PUR hot melt adhesive in composite fabrics

Note : The black arrow points to the PUR glue application point

Advantages

Cost calculation can reduce costs by 30%

No waste water and waste gas

High degree of automation and easy management

Instructions for use of solvent-free PUR polyurethane hot melt adhesive

Solvent-free PUR polyurethane composite adhesive PUR-103 is a single-component solvent-free with 100% solid content Polyurethane composite glue. PUR (PolyurethaneReactive) is a moisture-curing reactive polyurethane hot melt adhesive. The main component is isocyanate-terminated polyurethane prepolymer. In the high temperature state after heating, PUR glueThe agent molecules react with moisture or active hydrogen substances in the air or on the adherend to form a partially cross-linked network structure, which makes the bonding strength, chemical resistance, heat resistance, hydrolysis resistance and other properties better than ordinary hot melt adhesives. The adhesiveness and toughness (elasticity) of PUR are adjustable, and it has the thermoplastic cold-setting properties of ordinary hot melt adhesives. The bonding operation is simple, the range of objects that can be bonded is wide, and the performance is highly adjustable.

Uses of solvent-free PUR polyurethane composite glue

Suitable for use between ordinary fabrics, fabrics treated with fluorine-containing materials, polyester elastic yarn, cotton, fibers, PVC, PET and TPU Composite; after composite, it is resistant to washing and has excellent dry cleaning performance.

Technical specifications of solvent-free PUR polyurethane composite adhesive

Project specifications

100% solid content technology: 13929430431

Component-NCO

Viscosity @90℃ about 6000mPa.s

Density at 23℃ 1.12g/cm3

Odor Weak odor at working temperature, odorless after curing

Transparent viscous liquid in color

Equipment reference temperature 90~120℃

Using temperature 90-120℃

Use of solvent-free PUR polyurethane composite glue Method

Coating amount: 5-35g/m2 depends on the composition of the fabric to be used. Sample testing is required before use

Operating temperature: 90-120℃

The curing cycle is 25°C, 36-48 hours (when the ambient humidity is above 70%)

The humidity needs to be adjusted according to the speed of the machine, the machine and the material. The maximum curing time is 3-4 days.

Precautions for solvent-free PUR polyurethane composite glue

Please avoid mixing with water or alcohol.

Make sure the container is sealed and stored in a cool, dry and ventilated place

This product must be used while wearing protective equipment and in a ventilated environment.

Keep away from children.

The application of PUR hot melt adhesive in the field of electronic products

With the development and popularization of electronic products such as mobile phones, tablets, computers, electrical appliances, wearable devices, etc., the application of electronic glue in this field Application requirements are also getting higher and higher. Mobile phones, TVs, etc. are also developing towards intelligence, integration, screwless, and frameless. Many traditional glues can no longer meet the development requirements of modern smart devices. PUR hot melt adhesive is a new type of glue developed to meet the development requirements of smart devices. Electronic product adhesives

So what are the outstanding advantages of PUR hot melt adhesive compared to other electronic glues, and why is it widely used in the field of electronic products?

1. After curing, PUR hot melt adhesive has strong adhesion and high strength, which can meet the bonding requirements of most electronic products.

2. Compared with other electronic glues, PUR hot melt glue is easier to control the thickness of the glue, so it can meet the design requirements of current narrow-bezel mobile phones.

3. PUR hot melt adhesive is a type of thermoplastic polyurethane. Products bonded with PUR hot melt adhesive are easier to disassemble and repair.

The above three characteristics of PUR hot melt adhesive determine that PUR hot melt adhesive has more advantages than other glues in the field of bonding electronic products.

PUR hot melt adhesive has become the industry’s first choice for bonding, sealing, lamination, connection, insulation, electronic protection and assembly. Specific applications include smartphone and tablet screen component assembly, learning machines, GPS navigators, wearable electronic devices, window bonding, shell structure bonding, battery bonding, flat sealing, PCB assembly and protection, etc.