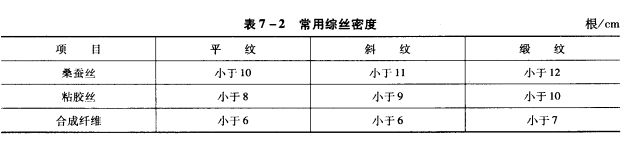

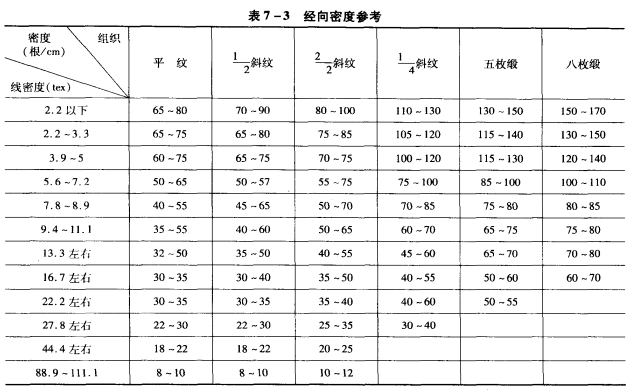

When designing plain fabrics, the density of warp and weft yarns has a greater impact on the loom construction. The details are as follows: (1) First, we must understand the maximum density range that the silk loom can weave. For example, the density range of the K274 silk loom is 6.9-114 threads/cm, and it has weavability as long as it is within this range during design. (2) In the warp direction, the effect of warp density on heddle density should be considered to study whether there is weavability. Of course, heddle density is not only affected by warp density, but also by fabric structure, warp raw materials, and heddle threading methods. Commonly used The heald density range is 7-2. If it exceeds this range, the number of healds should be increased accordingly.  Heald density (root/cm) = number of inner warp wires (reed inner width The warp and density design of the patterned fabric is restricted by the number of needles on the jacquard machine and the width of the pattern. The fabrication form is usually determined based on the warp density and pattern width. When the pattern width and number of needles are certain, to increase the density, hoisting can be used. But this must be within the allowable range of the number of needles. In addition, the increase or decrease in warp density is also restricted by the number of ground tissue cycles. In short, the design of warp and weft density is affected by many factors and should be considered comprehensively. Based on silk, viscose silk and tussah silk, the commonly used linear density and tissue density requirements are listed in Table 7-3 for reference during design. Since the weft density can be adjusted during the trial weaving process, the weft density design has greater flexibility. However, some fabrics that have strict requirements on pattern appearance, such as group flowers, squares, elephant scenes, etc. cannot be adjusted arbitrarily, otherwise it will cause The pattern is deformed and becomes a defective product. When designing, the weft density of the fabric is generally less than the warp density. This is mainly due to the thin linear density of the warp yarns, good quality of the warp yarns, high tension on the machine, and sufficient mercerization, which has a greater impact on the quality of the fabric. A small weft density has It is conducive to improving production efficiency and making weaving defects easy to remove. The meridional density reference is shown in Table 7-3.

Heald density (root/cm) = number of inner warp wires (reed inner width The warp and density design of the patterned fabric is restricted by the number of needles on the jacquard machine and the width of the pattern. The fabrication form is usually determined based on the warp density and pattern width. When the pattern width and number of needles are certain, to increase the density, hoisting can be used. But this must be within the allowable range of the number of needles. In addition, the increase or decrease in warp density is also restricted by the number of ground tissue cycles. In short, the design of warp and weft density is affected by many factors and should be considered comprehensively. Based on silk, viscose silk and tussah silk, the commonly used linear density and tissue density requirements are listed in Table 7-3 for reference during design. Since the weft density can be adjusted during the trial weaving process, the weft density design has greater flexibility. However, some fabrics that have strict requirements on pattern appearance, such as group flowers, squares, elephant scenes, etc. cannot be adjusted arbitrarily, otherwise it will cause The pattern is deformed and becomes a defective product. When designing, the weft density of the fabric is generally less than the warp density. This is mainly due to the thin linear density of the warp yarns, good quality of the warp yarns, high tension on the machine, and sufficient mercerization, which has a greater impact on the quality of the fabric. A small weft density has It is conducive to improving production efficiency and making weaving defects easy to remove. The meridional density reference is shown in Table 7-3.

AAA composite fabric mesh DFGE465IU8GHYJ

Composite fabric information on the relationship between fabrication and density

When designing plain fabrics, the density of warp and weft yarns has a greater impact on the loom construction. The details are as follows: (1) First, we must understand the maximum density range that the silk …

This article is from the Internet, does not represent Composite Fabric,bonded Fabric,Lamination Fabric position, reproduced please specify the source.https://www.yjtextile.com/archives/37361