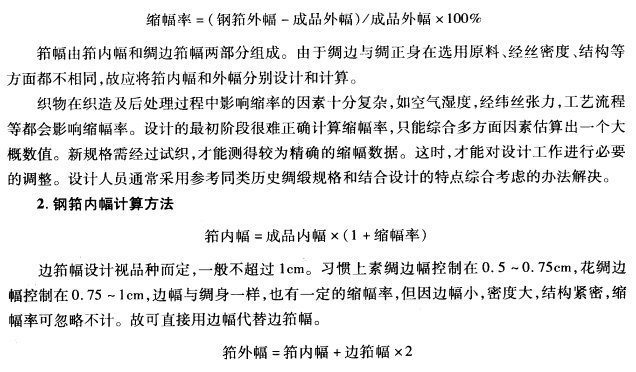

(1) The basis for determining the reed width. The width of the finished fabric is also called the door width, and the unit is cm. Generally, the reed width is calculated based on the finished product width. At the same time, the design of the finished product width is also restricted by the weaving process and dyeing and finishing process. The main purpose of silk fabric is to make clothing, and the width also changes with the styles of clothing and people’s wearing habits. Its other use is decoration, and its width is determined by the structure and requirements of the clothing content. From the perspective of ease of production and management, we do not want the fabric width specifications to be too complicated. With the development of the garment industry, mechanized cutting does not want too many width specifications. Therefore, it is advocated to merge silk fabric widths within a period of time based on consumption characteristics and production possibilities, and work towards the goal of standardization and unification. There are two types of finished width gauges, namely fixed type and variable type. The fixed type mostly appears in the design of decorative silks, such as quilt covers, bedspreads, table rugs, cushions, etc. The specifications are uniform, and the width depends on the decorative object, and generally does not make excessive changes; the variable type is suitable for the design of clothing silks. For example, the same variety can have multiple different widths to meet people’s needs for tailoring various clothing and different body shapes. Judging from the development trend, whether it is domestic sales or export sales, there is a trend of development in a broad direction. (2) Reed width calculation 1. Estimation: Since the warp and weft threads of the fabric maintain a large tension on the machine, the tension disappears after falling off the machine, and a certain amount of shrinkage will inevitably occur. In addition, raw woven silk still needs to be bleached and dyed, which will also produce a certain amount of shrinkage. The weaving shrinkage caused by weaving and the scouring shrinkage caused by scouring and bleaching are converted into percentages, collectively referred to as the shrinkage rate. The formula is as follows:

AAANHJJGHSFW

Reed design composite fabric information

(1) The basis for determining the reed width. The width of the finished fabric is also called the door width, and the unit is cm. Generally, the reed width is calculated based on the finished product width. At …

This article is from the Internet, does not represent Composite Fabric,bonded Fabric,Lamination Fabric position, reproduced please specify the source.https://www.yjtextile.com/archives/37362